- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

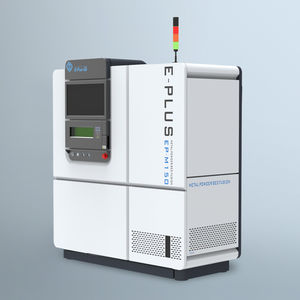

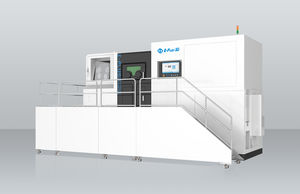

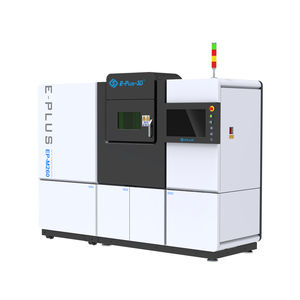

Large-format 3D printer EP-M450Hmetalpowder bed fusionindustrial

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- metal

- Technology

- powder bed fusion

- Applications

- industrial

- Other characteristics

- high-speed, large-format

- X travel

450 mm

(17.72 in)- Y travel

450 mm

(17.72 in)- Z travel

1,080 mm

(42.52 in)- Build space

200 l

(53 gal)- Layer thickness

Max.: 120 µm

Min.: 20 µm

- Printing nozzle speed

8 mm/s

- Weight

15,000 kg

(33,069.34 lb)

Description

With a building chamber size of 455*455*1100 mm³, Eplus3D Introduces EP-M450H to the successful line of MPBF 3D printers. The new EP-M450H is a marvelous metal printer that makes the production of reliable and high quality large metallic parts viable on industrial scale without requiring any tools.

The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Die Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is siutable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Features:

HIGH QUALITY

Printed parts' density > 99.9 %, deviation in parts' mechanical properties < 5 %; Repeatable positional accuracy along Z-axis of building direction ≤±5 μm; Overlapping deviation with dual laser printing ≤±0.1 mm; Overall mechanical properties of the printed part remains same when compared to printing results with the single laser machine.

HIGH EFFICIENCY

Build chamber size (X*Y*Z): 455*455*1100 mm³, build chamber volume >200 L; Optional dual laser system with 2*500 W fiber lasers increases printing efficiency by 70 %; Maxiumum building rate of 55 cm3/h.

COST-EFFECTIVE & EASY OPERATION

Blow back enabled coarse and fine filtration system ensures prolonged lifetime of filter over 1000 hrs; Highly user friendly software interface and one-click printing technology makes printing super simplified.

VIDEO

Catalogs

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- High-speed 3D printer

- High-performance 3D printing machine

- Metal additive manufacturing machine

- Large-format 3D printing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Polyamide 3D printer

- Nylon 3D printing machine

- 3D printer for the aerospace industry

- 3D printing powder

- 3D printer for the automotive industry

- Laser sintering 3D printer

- PP 3D printer

- Mold manufacturing 3D printer

- Plastic 3D printing powder

- 3D printing software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.