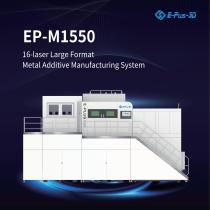

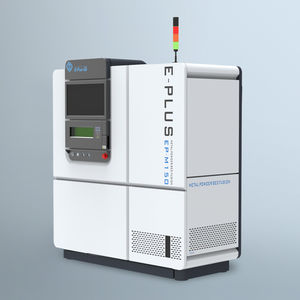

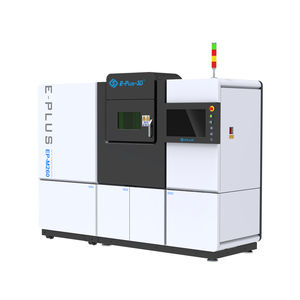

Metal 3D printer EP-M1550aluminum alloystainless steelindustrial

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- metal, aluminum alloy, stainless steel

- Applications

- industrial, prototyping, medical, for orthodontics, construction

- Technology

- powder bed fusion

- Other characteristics

- high-speed, high-performance

- X travel

1,550 mm

(61.02 in)- Y travel

1,550 mm

(61.02 in)- Z travel

1,100 mm

(43.31 in)- Layer thickness

Max.: 120 µm

Min.: 70 µm

Description

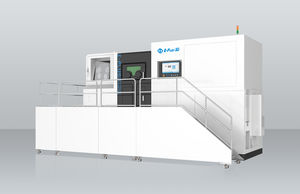

EP-M1550 is using a large building envelope and 16-laser system to ensure high-efficiency production. The multi-laser precise positioning and innovative area splicing control technology offer uniformity and stability throughout the whole printing phase.

Compatible with titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel and cobalt chrome, etc. EP-M1550 is an ideal choice for direct manufacturing of large-size, high-precision, and high-performance parts for aerospace & aviation and other industries.

HIGH EFFICIENCY & HIGH PRODUCTIVITY

-Printing of oversize parts in the 2670 Liter build chamber.

-16 lasers are printing simultaneously with speed up to 650 cm³/h.

-Excellent beam and power stability, as well as energy control strategies can inhibit porosity, micro-cracks and non-fusion defects.

EXCELLENT QUALITY & GOOD CONSISTENCY

-Excellent high beam quality (M²≤1.1) and detail resolution ensure the forming accuracy and mechanical properties of printed parts.

-Print density > 99.9% and fluctuation of mechanical properties < 5%.

-Optimized design of wind field structure ensures effective removal of dust and splash and uniform printing of full-format parts.

HIGH INTELLIGENTIZATION & AUTOMATION

-User-friendly interface with fully automatic one click printing and one-click pickup function.

-With automatic cleaning (backblowing), the filtration system can realize online back blowing during printing.

-Equipped with permanent filter elements.

-The build job information is displayed in real time with traceable printing parameters report.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Additive manufacturing machine

- Industrial 3D printing machine

- Plastic 3D printing machine

- Model making 3D printer

- High-speed 3D printer

- High-performance 3D printing machine

- Metal additive manufacturing machine

- Large-format 3D printing machine

- Medical additive manufacturing machine

- Dental additive manufacturing machine

- Polyamide 3D printer

- Nylon 3D printing machine

- 3D printer for the aerospace industry

- 3D printing powder

- 3D printer for the automotive industry

- Laser sintering 3D printer

- PP 3D printer

- Mold manufacturing 3D printer

- Plastic 3D printing powder

- 3D printing software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.