Designed for measuring small measuring strain ranges as required for proof load testing of bolts and similar applications such as yield measurement.

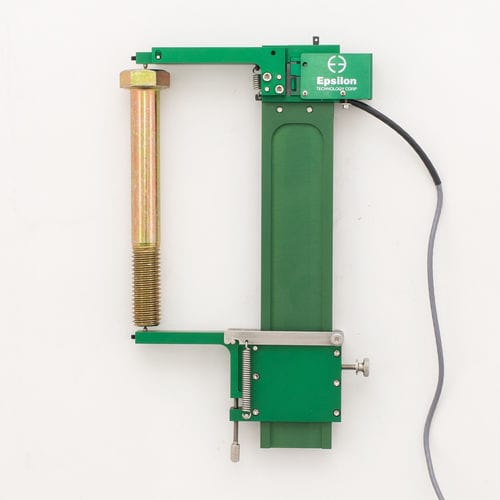

The Model 3565 uses hard conical points to contact the bolt at the center of the head and at the bottom. It is fully adjustable for different length bolts ranging from 25 mm (1 inch) in length to 150 mm (6 inches) standard. Extension beams are available for longer bolts. The standard maximum measuring range is 1.25 mm (0.05 inches). Generally, on longer bolts this extensometer will be self-supported without requiring any centering marks or punch marks on the bolt. For shorter bolts these marks may be required. If the conical pins are sharp, marks are often not needed even on the shortest bolts.

The extensometer has a zero adjustment screw to adjust the length between the contact pins. This is used to set the output voltage to zero, which corresponds to the correct starting position for the test. It also includes a breakaway lower arm. In the event a bolt should fail, the breakaway arm snaps free, helping to prevent damage to the extensometer. This is easily re-installed. In the event that bolt failures are likely during a test, it is recommended the user attach a cord around the upper part of the beam and tie the other end to the test frame to prevent the extensometer from falling. The conical point contacts included with the extensometer are made from tungsten carbide.