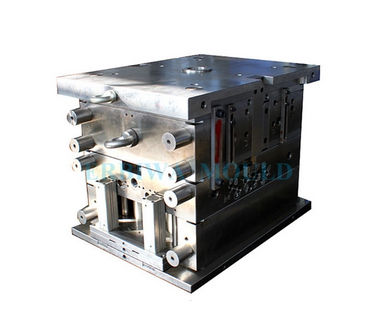

Mold Type - Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc

Design software - UG, ProE, AutoCAD, Solidworks, etc

Main services - Prototypes, mold design, mold making, mold tesing,

low volume/high volume plastic production

Certificate - ISO9001: 2015; IATF16949: 2016

Steel material - 718H, P20, NAK80, S316H, SKD61, etc

Plastic production Raw material - PP, PA6, PLA, ABS, PE, PC, POM, PVC, PET, PS, TPE/TPR, etc

Mold base - HASCO, DME, LKM, etc

Mold runner - Cold runner and hot runner

Mold hot runner - DME, HASCO, YUDO, etc

Mold cold runner - Point way, side way, follow way, direct gate way, etc

Mold strandard parts - DME, HASCO, etc

Mold life - According to client's requirements

Mold hot treatment - Quencher, nitridation, tempering, etc

Mold cooling system - Water cooling or Beryllium bronze cooling, etc

Mold surface - EDM, texture, high gloss polishing

Hardness of the steel - 20~60 HRC

Equipments - High speed CNC, standard CNC, EDM, Wire cutting, Grinder,

Lathe, Milling machine, plastic injection machine

Lead time - 35~55 working days

Month Production - 50 sets per month

Mold Packing - Standard exporting Wooden case