- Industrial machines and equipment

- Furnace and Heat Treatments

- Vacuum dryer

- EREMA Engineering Recycling Maschinen und Anlagen

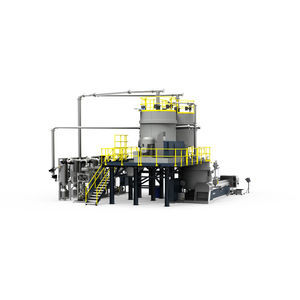

Vacuum dryer VACUREMA® MPR®in-linefor plasticsfor bottles

Add to favorites

Compare this product

Characteristics

- Technology

- vacuum

- Batch/continuous

- in-line

- Applications

- for bottles, for plastics

- Associated function

- reactor

Description

This crystallisation dryer makes the difference. The patented Multi Purpose Reactor, MPR for short,® is the highly effective complement for existing extrusion plants. The washed PET input material – bottle flakes, ground PET flat sheet waste and virgin material plus mixtures of them – is turned into clean, dry, dust-free, crystallised and food-contact-compliant flakes even before extrusion. You also have the option of using the MPR® as a stand-alone solution (without subsequent extrusion).

Possible materials

It's amazing what you can recycle with VACUREMA® MPR. Here are some examples.

Your benefits

Economical and technically better.

Increased temperature and vacuum for effective decontamination, drying and crystallisation of PET

Easy to retrofit on existing extrusion plant

Better flake colour results thanks to vacuum processing

High profitability

PET flakes that are clean, dry, dust-free, crystallised and food contact compliant even before extrusion

VIDEO

Catalogs

No catalogs are available for this product.

See all of EREMA Engineering Recycling Maschinen und Anlagen‘s catalogsOther EREMA Engineering Recycling Maschinen und Anlagen products

VACUREMA

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.