- Production Machines

- Plastics Processing

- Sheet extrusion line

- EREMA Engineering Recycling Maschinen und Anlagen

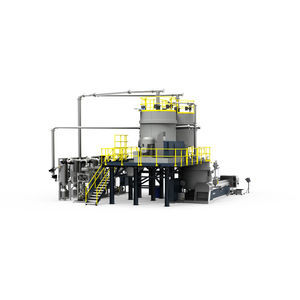

Sheet extrusion line EcoGentle®for thermoplasticsfor PET bottle flakes

Add to favorites

Compare this product

Characteristics

- Type

- sheet

- Treated material

- for thermoplastics

- Applications

- for PET bottle flakes

Description

Whether VACUREMA® Basic, Advanced or Prime, or VACUNITE® - EcoGentle® is the ultimate plasticising technology for PET recycling. It combines gentle melt treatment with signifi cantly reduced energy consumption in a unique way. This saves you money on production costs. For high cost effectiveness, productivity and top-quality rPET end products.

Extrusion the gentle way

Newly developed EcoGentle® plasticising technology, in combination with EREMA's proven Counter Current® technology, ensures perfect interaction between the feed section and the extruder screw. Temperature and energy requirements are greatly reduced, while at the same time improving melting and mixing performance in the plasticising unit.

The core elements of the innovative EcoGentle® technology are the adjustment of compression ratios for better solids handling behaviour, the targeted utilisation of shear flows in combination with elongation flows, and a number of other process and rheological optimisations. The perfectlymatched interaction between the shear and elongation flows increases both the melting performance and the dispersive and distributive mixing capacity in the plasticising unit.

Wider process window, more stable operation

The result is particularly gentle plasticising combined with high melt homogeneity and a wide process window for more stable operation. Variations in parameters such as the bulk density of the input material, viscosity or temperature of the PET flakes can be compensated as part of the stable process.

Catalogs

No catalogs are available for this product.

See all of EREMA Engineering Recycling Maschinen und Anlagen‘s catalogsOther EREMA Engineering Recycling Maschinen und Anlagen products

VACUREMA

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Panel extrusion line

- Plastic pelletizer

- Single-screw screw extruder

- Polypropylen extrusion line

- Compact pelletizer

- Polyethylene extrusion line

- PP screw extruder

- PE screw extruder

- Twin-screw extrusion line

- ABS screw extruder

- Dry pelletizer

- Compact screw extruder

- Pelletizer for the plastics industry

- PS screw extruder

- PET extrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.