- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

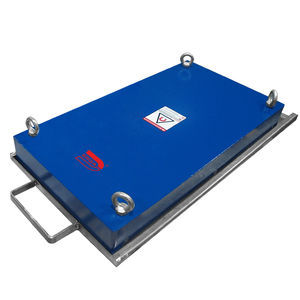

Double-drum separator DrumMag DMmagnetic drummetalfor bulk materials

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic drum

- Separated substance

- metal, for bulk materials, dry materials

- Application domain

- for the food industry, for the recycling industry, for the chemical industry, construction, for ore

- Other characteristics

- automatic, dry, double-drum

Description

Automatic magnetic separator for continuous recovery of metal inclusions from fine dusty material.

- Minimum losses of fines during separation:

The separator is specially designed for difficult task of removing small magnetic impurities from dusty material in dry environment. Maximally isolated zones of separation and discharge of products help to minimize loss of valuable finely dispersed product;

- Pure magnetic fraction:

Availability of the second auxiliary drum for recovery and transportation of magnetic inclusions to the discharge zone, as well as intense magnetic stirring, ensure high concentration of magnetic particles in the end product. DrumMag DM separator is used for processing nickel and iron slags, bottom ash and fly ash, crushed magnetite, iron and chrome ores, dedusting plant dust, dolomites, magnesites, expanded clay and other refractory materials at processing plants in glass, refractories and abrasive industries;

- Dry separation method:

DrumMag DM double drum separator allows you to improve material quality with lower energy consumption without additional financial and time expenditures for water and drying;

- Sealed housing:

The sealed housing provides comfortable operation with dusty materials indoors without any harm to the operators’ health;

- Automatic cleaning

- Operation with abrasive materials:

The separator operating surface is made of durable abrasion-resistant chrome-nickel steel. In case of operation in highly abrasive medium, the separator shell is additionally lined with wear plates.

Related Searches

- Rail conveyor

- Belt conveyor

- Horizontal rail conveyor

- Solid classifier

- Feeder

- Centrifugal classifier

- Liquids separator

- Electric drive conveyor

- Eddy current separator

- Sorting machine

- Inclined conveyor

- Process classifier

- Gravity classifier

- Automatic sorting machine

- Bulk products conveyor

- Classifier for the recycling industry

- Classifier for the food industry

- Ferrous metal separator

- Optical sorting machine

- Automatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.