- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

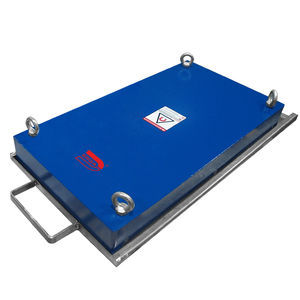

Eddy current separator EddyFlow Emetalfor non-ferrous metalswaste

Add to favorites

Compare this product

Characteristics

- Technology

- eddy current

- Separated substance

- metal, for non-ferrous metals, waste, plastic, chip, cable

- Application domain

- for the food industry, for the recycling industry, for the chemical industry, construction, foundry

- Other characteristics

- high-efficiency, compact, mining

- Weight

Min.: 550 kg

(1,212.54 lb)Max.: 1,650 kg

(3,637.63 lb)

Description

ERGA EddyFlow and EddyFlow E eddy current magnetic separators ensure recovery of nonferrous metals from nonconductive materials in processing of mixed municipal waste, shredded cable, plastics, WEEE, cullet, scrap, wood chips, incineration bottom ash, smelters’ nonferrous slags.

- Separation/cleaning efficiency up to 99.8%:

Customized separation mode is selected depending on feed material. Precise adjustment of splitter position and magnetic rotor speed up to 3000 rpm help to achieve 99.8% of feed material separation and cleaning efficiency;

- Recovery of metal particles from 3 mm;

- Fine adjustment of separation mode:

Capability to control conveyor belt speed and frequency of rotation of the magnetic rotor by means of frequency converters ensure quick setting of ERGA EddyFlow and ERGA EddyFlow E operation modes for maximum separation efficiency;

- Highly efficient NdFeB magnetic system:

Depending on operation specifics and conditions eddy current separators are designed as EddyFlow E model with eccentric arrangement of magnetic rotor relative to the drum axis or as EddyFlow with concentric rotor. Rotor configuration and the number of poles determine efficiency of extraction of nonferrous metals. Unique patented NdFeB magnetic systems provide long-term efficient operation of magnetic separators. Guaranteed period of magnetic systems properties, subject to operating rules, is 10 years;

- Easy assembly and operation:

Smart design provides quick belt change, protects the magnetic rotor from tramp metal under the belt, simple design of bearing assemblies increases reliability and also guarantees maintainability of the magnetic rotor, which reduces equipment downtime.

Related Searches

- Rail conveyor

- Belt conveyor

- Horizontal rail conveyor

- Solid classifier

- Feeder

- Centrifugal classifier

- Liquids separator

- Electric drive conveyor

- Eddy current separator

- Sorting machine

- Inclined conveyor

- Process classifier

- Gravity classifier

- Automatic sorting machine

- Bulk products conveyor

- Classifier for the recycling industry

- Classifier for the food industry

- Ferrous metal separator

- Optical sorting machine

- Automatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.