- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

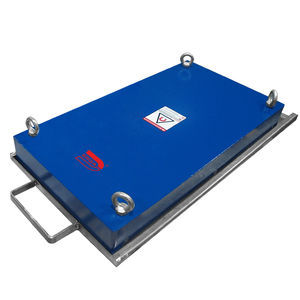

Wet separator WetMagmagnetic drumpermanent magnetsludge

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic drum, permanent magnet

- Separated substance

- sludge

- Application domain

- for the chemical industry, construction, for ore

- Other characteristics

- self-cleaning, high-efficiency, iron, wet, high-intensity, permanent magnet

Description

Self-discharging ERGA WetMag permanent magnetic drum separator is designed for automatic continuous recovery of strongly magnetic inclusions from slurries and process media.

- Permanent magnetic system:

The magnetic field parameters are selected individually depending on magnetic susceptibility of concentrated material:

- for recovery of strongly magnetic concentrate (magnetite ore dressing, CHP plant ash, removal of industrial iron) the recommended magnetic intensity in the operating area is 0.08-0.24 T;

- for getting tailings with minimum content of useful magnetic product or for recovery of less magnetic materials (oxidized industrial iron, ferromanganese minerals, etc.), the recommended intensity in the operating area is 0.24-0.4 T.

- Special magnetic system for wet separation process:

Special magnetic system design is used for this type of equipment. The magnetic system features are deep magnetization of the operating zone for maximum recovery of magnetic particles and high-intensity magnetic stirring for breaking magnetic floccules and receiving magnetic concentrate.

- Efficient recovery of magnetic inclusions of various sizes:

Efficient recovery of magnetic inclusions in separated fractions is achieved by customized selection of the required bath type:

- concurrent bath is used for coarse material (up to 10mm);

- countercurrent bath is for material size up to 3 mm;

- semi-countercurrent bath is for fine material (98% less than 0.071 mm).

- Wet separation method:

The wet separation process allows for processing of a wide range of particle sizes to produce high-quality saleable magnetic concentrate.

- Protection of operating surfaces

Related Searches

- Rail conveyor

- Belt conveyor

- Horizontal rail conveyor

- Solid classifier

- Feeder

- Centrifugal classifier

- Liquids separator

- Electric drive conveyor

- Eddy current separator

- Sorting machine

- Inclined conveyor

- Process classifier

- Gravity classifier

- Automatic sorting machine

- Bulk products conveyor

- Classifier for the recycling industry

- Classifier for the food industry

- Ferrous metal separator

- Optical sorting machine

- Automatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.