- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

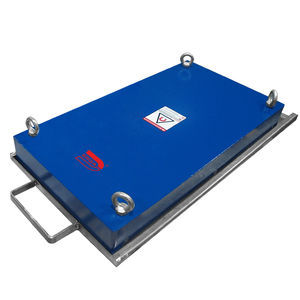

Magnetic plate separator PlateMag Vmetalfor the food industryfor the chemical industry

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic plate

- Separated substance

- metal

- Application domain

- for production lines, for the food industry, for the chemical industry, construction

- Other characteristics

- high-efficiency, high-performance, iron

- Length

630 mm, 960 mm

(25 in, 38 in)- Width

355 mm, 420 mm

(14 in, 17 in)- Weight

200 kg, 350 kg

(440.92 lb, 771.62 lb)

Description

Plate iron separator ERGA PlateMag V with casing designed for pressuried operation is installed in a gravity circular pipeline and ensures efficient cleaning of material transported by pneumatic and vauum conveors, cement pipelines.

High performance of cleaning material from impurities

Under pressure difference in the pipeline cross section, material enters the magnetic separator, where it is transported between two magnetic plates installed on opposite sides of the gravity pipe. The magnetic system parameters are customized, taking into account peculiarities of the customer’s production, thus guarantee maximum efficient cleaning of material from impurities with high capacity.

Efficient and inexpensive plate iron separators of PlateMag V series are widely used in cement plants, aggregate production plants for construction industry, chemical facilities, as well as flour mills and bakeries.

Reliable retention of fines

Work surfaces of the magnetic plates are equipped with special ribs forming the so-called shadow zones, necessary for reliable retention of metal fines and preventing their flow with the rest of material.

Easy assembly and operation

The product design has a proven geometry of the casing, eliminating excessive wear, and all necessary reinforcements to ensure long-term operation.

ERGA PlateMag V iron separators are integrated into the required process line section and does not need any additional redesign. For easy installation backing and fastening flanges are used in PlateMag V design. A spare kit of adapter flanges is available for order.

Related Searches

- Rail conveyor

- Belt conveyor

- Horizontal conveyor

- Solid classifier

- Feeder

- Centrifugal classifier

- Liquids separator

- Electric drive conveyor

- Eddy current separator

- Sorting machine

- Inclined conveyor

- Process classifier

- Automatic sorting machine

- Gravity classifier

- Bulk products conveyor

- Classifier for the recycling industry

- Classifier for the food industry

- Ferrous metal separator

- Optical sorting machine

- Automatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.