- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

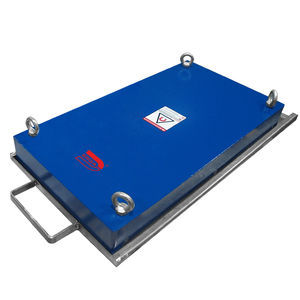

Wet drum separator WetMag Rpermanent magnetsludgefor solids

Add to favorites

Compare this product

Characteristics

- Technology

- wet drum, permanent magnet

- Separated substance

- sludge, for solids

- Application domain

- for the chemical industry, for ore, construction

- Other characteristics

- automatic, self-cleaning, high-efficiency, wet, high-intensity, mining, permanent magnet

- Length

2,359 mm, 2,609 mm, 3,518 mm, 3,531 mm, 4,183 mm

(93 in, 103 in, 139 in, 139 in, 165 in)- Width

2,054 mm, 2,100 mm, 2,127 mm, 2,483 mm, 2,606 mm

(81 in, 83 in, 84 in, 98 in, 103 in)- Weight

2,400 kg, 2,600 kg, 5,500 kg, 6,000 kg, 7,800 kg

(5,291.09 lb, 5,732.02 lb, 12,125.42 lb, 13,227.74 lb, 17,196.06 lb)

Description

Self-discharging ERGA WetMag R permanent magnetic drum separator is designed for automatic continuous dense media recovery.

Reduction in expenses for dense-medium solids (magnetite, ferrosilicon)

Special design of the separator, coupled with high magnetic characteristics of the permanent magnet system, provides maximum recovery of magnetite or ferrosilicon from slurry (up to 99.8%).

Permanent magnetic system

Wet drum separator WetMag R successfully replaces EBM type electromagnetic separators without any losses in performance and efficiency of magnetite recovery due to the developed magnetic system (angle 270°) with high-energy permanent magnets. There are no operational costs associated with the maintenance of technically complex electromagnetic system.

For one year of operation WetMag R separator can save tens of thousand dollars in electricity consumption compared to electromagnetic analogs.

Special design for efficient recovery

Special design of the separator bath provides deep sinking of the drum in the slurry, increasing magnetite recovery zone. This provides higher process efficiency of the separators in comparison with PBM type permanent magnetic separators. The magnetic system has field distribution along the entire drum width without induction gaps and maximum number of poles to ensure stirring and breaking of the floccules, which provides the cleanest concentrate.

Availability of drying scraper instead of the flushing nozzle for magnetic fraction removal ensures getting product with the required solids: liquids ratio.

Related Searches

- Rail conveyor

- Belt conveyor

- Horizontal conveyor

- Solid classifier

- Feeder

- Centrifugal classifier

- Liquids separator

- Electric drive conveyor

- Eddy current separator

- Sorting machine

- Inclined conveyor

- Process classifier

- Automatic sorting machine

- Gravity classifier

- Bulk products conveyor

- Classifier for the recycling industry

- Classifier for the food industry

- Ferrous metal separator

- Optical sorting machine

- Automatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.