- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

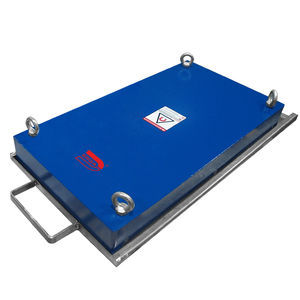

Permanent magnet separator TrunMaggravitymetalwaste

Add to favorites

Compare this product

Characteristics

- Technology

- permanent magnet, gravity

- Separated substance

- sludge, metal, waste

- Application domain

- for ore, construction

- Other characteristics

- automatic, self-cleaning, high-efficiency, mining, permanent magnet

Description

ERGA TrunMag magnetic system provides continuous and automatic removal of grinding ball fragments from the ground products of ball, rod and SAG mills.

Protection of expensive equipment from damage and premature wear

Powerful permanent magnet system (sector with 2000 angle) removes and discharges grinding ball fragments into the discharge zone, preventing wear and damage of the transportation, classification and pumping equipment caused by the presence of metal parts and fragments in the product. The iron scrap removal from the milling cycle with TrunMag magnetic separation plants allows for 2-4 times reduction of wear rate of transportation systems, pump, classifying and other equipment, accordingly reducing maintenance and repair costs.

Improvement of ore dressing process

When metal scrap gets into the process, ore dressing values at the stage of rough concentrate separation decrease. Removing scrap from the technological process in gold ore processing increases the yield of rough concentrate by 1.5% and recovery of gold in rough gravity concentrate by 9.2% from the operation.

Customized solution for various mill sizes

Many years of manufacturing experience allow ERGA to provide custom solutions of the problem: design and produce trunnion magnets for specific mill sizes, taking into account their mounting dimensions.

Easy installation and operation

The magnetic system drum is mounted on the discharge flange of the balling drum. The drum is designed for mounting trammel and has the same mounting dimensions, minimum size and represents a space ring. The magnetic sector is mounted on its own supports and requires preparation of the site for its installation.

Related Searches

- Rail conveyor

- Belt conveyor

- Horizontal conveyor

- Solid classifier

- Feeder

- Centrifugal classifier

- Liquids separator

- Electric drive conveyor

- Eddy current separator

- Sorting machine

- Inclined conveyor

- Process classifier

- Automatic sorting machine

- Gravity classifier

- Bulk products conveyor

- Classifier for the recycling industry

- Classifier for the food industry

- Ferrous metal separator

- Optical sorting machine

- Automatic conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.