- Products

- Plastic laminating machine

- Erhardt + Leimer

- Products

- Catalogs

- News & Trends

- Exhibitions

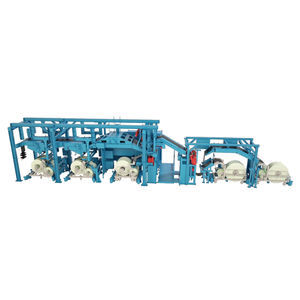

Plastic laminating machine EL.TAG

Add to favorites

Compare this product

Characteristics

- Applications

- for plastics

Description

The EL.TAG machine has the higher level task of placing an RFID tag (chip including the antennas) between two rubber strips.

For this, a rubber strip is fed into the machine, and strips are cut off from it using an ultrasonic knife. A robot creates sandwiches from these sections and the RFID chip (including antenna). These consist of two rubber sections and an RFID chip in between. Then, after cold lamination, the sandwich is placed on a plastic carrier using a Pick-and-Place unit and the carrier is wound up for further processing. The entire process and the function of the finished product is monitored by a 2D camera in the work area, a 3D camera after lamination and an RFID reader before rewinding.

Area of use

Independent machine in the tire industry

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.