- Products

- Catalogs

- News & Trends

- Exhibitions

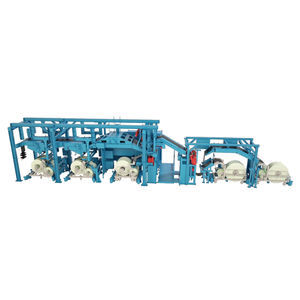

Air blast cleaning system automatic

Add to favorites

Compare this product

Characteristics

- Technology

- air blast

- Operational mode

- automatic

Description

The automatic cleaning system is designed for liner cleaning used on the calendar or extrusion lines to ensure uninterrupted production and high quality. A lot of different solution are available to adapt the machine for each bobbins and cassettes.

•Inlet and outlet liner stock

•Automatic material threading

•Driven beating roller

•Driven brushes

•Adjustable air blade

•Each group are equipped with one suction system

•Automatic material run out detection

•Residual rubber monitoring and detection

•ELGUIDER Guiding device

•Edge defect detection

•Liner material spreading

•ELTENS Tension control with automated run out knot sensor

•Automatic forward of unwind/ rewind cores

Your production will gain

•Extended life of liner

•Reduction in residual sulfur results in order to improve the vulcanization process

•Reduction in liner replacement cost

•Detection of defects and contamination

•Improvement of the tire production quality

Function

•Guiding

•Cleaning

•Tension control

Application

•Fabric liner (Cretonne)

•Polythene foil

•Polyester

•Plastic film

•Others

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.