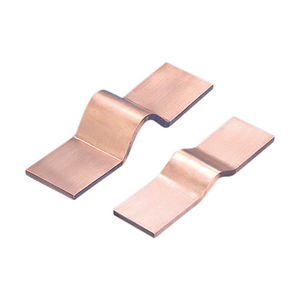

Flexible busbar FLEX2MRCcopperinsulatedself-extinguishing

Add to favorites

Compare this product

Characteristics

- Material

- copper

- Electrical characteristics

- insulated

- Structure

- flexible

- Protection level

- self-extinguishing

- Primary current

Max.: 2,800 A

Min.: 125 A

Description

Thin layers of bare electrolytic copper formed into a stack

Full range from 19.5 mm² up to 1200 mm² and 125 A to 2800 A

Insulated by high-resistance, self-extinguishing PVC with less than 20% contact with conductor for high flexibility

Easily bent, folded, and twisted, improving assembly flexibility, shortening connections, and decreasing footprint

Dramatically smaller and more flexible than comparable cable based on ampacity

Better power density than cable with lower skin effect ratio

Connections made by punching and bolting directly through the copper laminates, clamping onto the end of the nVent ERIFLEX Flexibar, or welding using nVent ERICO Cadweld

No lugs needed, reducing installation time and improving resistance to vibration

Weight savings and material savings compared to wire alternatives

Reduces total installation cost

Traceability codes and designation part numbers printed on insulation

100% production dielectric tested

UL 758 Appliance Wiring Material requirements for Cold Bend testing at -40°C and -50°C (-40°F and -58°F)

EAC compliant

RoHS compliant

Length: 2 000 mm

Material: Copper; Polyvinylchloride

Dielectric Strength: 20 kV/mm

Flammability Rating: UL® 94V-0

Insulation Elongation: 370 %

Insulation Thickness: 2 mm

Nominal Voltage, UL/CSA/IEC: 1 000 VAC; 1 500 VDC

Working Temperature: -50 to 105 °C

Forming Temperature: 0 – 55 °C

Certification Details: UL® 67; UL® 758

Complies With: IEC® 60439.1; IEC® 61439.1; IEC® 61439.1 Class II; IEC® 60695-2-11 (Glow Wire Test 960 °C)

VIDEO

Catalogs

No catalogs are available for this product.

See all of ERICO‘s catalogsRelated Searches

- Electrical connector

- Electrical cable

- Electrical power supply connector

- Copper cable

- Copper electrical cable

- Metal electrical connector

- Power cable

- Round electrical connector

- Insulated cable

- Insulated electrical cable

- Junction block

- Rectangular electrical connector

- Cable conduit

- Flexible cable

- Protection conduit

- Flexible electrical cable

- IEC electrical cable

- Plastic conduit

- Solderless terminal

- Flame-retardant cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.