- Production Machines

- Other Manufacturing Equipment

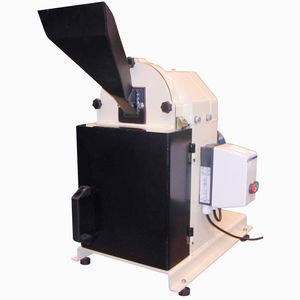

- Mill with rods

- Eriez Magnetics Europe Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Ball grinding mill L14 serieswith rodshorizontalstone

Add to favorites

Compare this product

Characteristics

- Technology

- ball, with rods

- Orientation

- horizontal

- Product applications

- stone

- Other characteristics

- stainless steel, laboratory

- Rotational speed

Max.: 69 rpm

(434 rad.min-1)Min.: 42 rpm

(264 rad.min-1)

Description

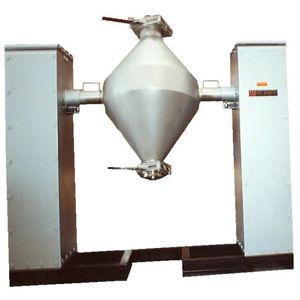

MACSALAB Rod / Ball Mill Vessels are available in Grade 304 and 316 Stainless Steel, Rubber - lined Mild Steel as well as Ceramic (Alumina).

Rods are available in Stainless Steel and Arlicite.

Grinding Spheres (balls) are available in Steel, Zirconia and Alumina. Quantity and sizes to client’s specifications.

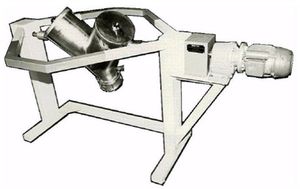

MACSALAB Drive Rolls for Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller.

Ball/Rod mill Literature

The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batch-wise, rapid grinding of medium-hard to very hard samples down to finest particle sizes.

A horizontal rotating cylinder (vessel) is partially filled with balls/rods (grinding media), usually stone or metal, which grinds material to the necessary fineness by friction and impact with the tumbling balls/rods. A rotating drum throws material and balls/rods in a counteracting motion which causes impact breakage of larger particles and compressive grinding of finer particles. Attrition in the charge causes grinding of finer particles.

Catalogs

No catalogs are available for this product.

See all of Eriez Magnetics Europe Limited‘s catalogsOther Eriez Magnetics Europe Limited products

Size Reduction and Laboratory Equipment

Related Searches

- Grinding mill

- Screening unit

- Bulk material screening unit

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- Rotor lump breaker

- Vibrating sieving machine

- Impact grinding mill

- Building materials grinding mill

- Hammer grinding mill

- Laboratory grinding mill

- Stainless steel grinding mill

- Compact grinding mill

- Mineral mill

- Floor-standing centrifuge

- Rotary drum grinding mill

- Linear vibrating screening unit

- Process centrifuge

- Ball grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.