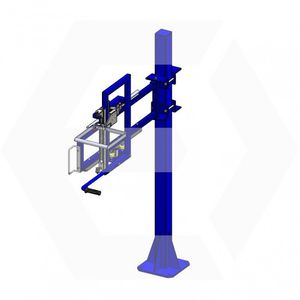

Semi-automatic filling machine ERIFUT 3 XNP LT DOSINGdrumfor packagingfor liquids

Add to favorites

Compare this product

Characteristics

- Operational mode

- semi-automatic

- Container type

- drum

- Product applications

- for packaging, for liquids

- Domain

- for the chemical industry, for the food industry, for the pharmaceutical industry, laboratory

- Type

- gravity, vertical

- Number of heads

- with 1 head

- Other characteristics

- 3-axis, ATEX

- Throughput

30 p/h

- Machine length

1,880 mm

(74 in)- Machine width

600 mm

(24 in)- Machine height

2,110 mm

(83 in)- Machine weight

313 kg

(690.05 lb)

Description

The ERIFUT 3 XNP LT DOSING allows the semi-automatic packaging in accordance with a target weight with a partial diving cane.

The ERIFUT 3 XNP LT DOSING is ergonomically designed to optimize the conditions of handling and operator exposure in an improvement process complies with REACH requirements :

• Control panel and deported maneuvering system

• No direct contact with the dip tube

• No direct exposure to the emanation or splashing (completely removed with an extractor hood)

• No awkward handling of the dip tube

This configuration is ideal for the semi-automatic filling of 4 barrels on pallet or a container.

The polar movement of filling device with locking in position allows to cover partially the surface of a pallet.

The diving system indexable (stroke 420 mm) to manually ensure diving the dip tube into the container with a blocking high and low position of the tube. The stops positioning units are adjustable in height to allow the modification of the race. An assist spring allows to help the rise of drumming device.

Filling is performed, based on a unit weight target, by an automatic filling cycle triggered by the operator

DOMAINS OF USE

Our machines are designed for industrial exploitation.

• Atmosphere without specific constraint.

• Atmosphere with specific constraint for use in chemical environments, food or pharmaceutique.For example: ISO 7 clean room or laboratory class D, GMP strain, ASM BPE, etc ..

• Our machines can meet the requirements of the ATEX directive for use in explosive atmosphere Zone 1,21 and 2,22.

Catalogs

No catalogs are available for this product.

See all of ERIMAC‘s catalogsRelated Searches

- Wrapping machine

- Bagging machine

- Liquid filler

- Filler for the food industry

- Automatic wrapping machine

- Vertical bagging machine

- Pallet wrapping machine

- Bulk material bagging machine

- Palletizer

- Bagging machine for the food industry

- Semi-automatic filler

- Turntable wrapping machine

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Case sealer

- Granulate bagging machine

- Container filler

- Powder bagging machine

- Adhesive tape case sealer

- Wrapping machine with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.