- Metrology - Laboratory

- Inspection and Monitoring

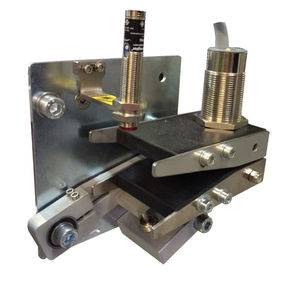

- Camera inspection system

- ERO Gluing Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

Gluing machine inspection system ERO-OCcameraquality controlcolor

Add to favorites

Compare this product

Characteristics

- Technology

- camera

- Type

- quality control, color

- Applications

- for production

- Product applications

- for gluing machine

- Other characteristics

- fast

Description

ERO-OC glue inspection system is controlled from a 12“ touch screen control or iPad, which provides real-time images of the production line, and can also display pictures of the last faulty box detected, for an in-depth gluing defect analysis. The system takes a picture of each box produced, up to 200 photos of faulty boxes can be saved. A data analyzer, encoder frequency divisor and stroboscopic illuminator are installed within an electrical cabinet.

■ Black & white camera.

■ Maximum speed: 350 m/min.

■ 128 high-efficiency LED stroboscopic camera illuminator.

■ Right side support for camera and illuminator OR left side support for camera and illuminator.

■ Illuminator driver.

■ Encoder divider.

■ Marker driver.

■ Low noise and 5 meters of protected camera cable.

■ 5 meters of illuminator cable.

■ 100% Glue control guaranteed for every type of color and format

■ Pictures are taken and shown in real time

■ Leading technology, fully compatible with the majority of glue systems

■ Complete report of production can be saved and printed

■ Easy handling

■ Smallest readable dot = Ø1.5 at 200 meters/minute.

■ Adjustable tolerance threshold to measure if glue levels are too low or too high.

■ Adjustable tolerance threshold for shifted glue pattern position at the beginning or at the end of glue patterns (Min. tolerance = 1 mm).

Catalogs

No catalogs are available for this product.

See all of ERO Gluing Systems‘s catalogsOther ERO Gluing Systems products

Quality Control for Flexo-Folder-Gluers

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.