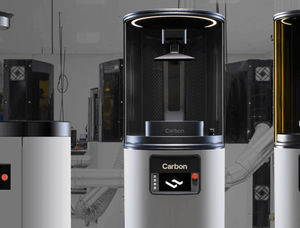

Resin 3D printing SLAprototyping

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- resin

- Technology

- SLA

- Applications

- prototyping

Description

Thanks to our 10 stereolithography machines, we are able to create a particularly accurate prototype or model working from a 3D CAD file. We are specialists in decorative elements (paint finish), precision parts and also very large scale objects with two systems with a capacity of 1500x750x550mm.

We use the very best resins to date, the Xtreme resin (grey) and Xtreme white. We are also able to produce clear pieces (Clearvue).

And we can also produce biocompatible pieces. Indeed the WaterShed XC resin has been given USP Class VI grading.

This technique is part of 3D printing by adding material. Also computer-assisted, it consists first of all in creating a digitized or 3D model of the part to be manufactured. This sketch, with all the details, is then transferred to the matrix of the stereolithography apparatus which will then be responsible for producing the 3D printing of the object. This process is widespread in the industrial field. This allows for prototyping within very tight deadlines. Now, the use of the process is no longer limited to the prototyping framework. Indeed, ready-made parts can also be produced. It is necessary to underline the great precision of the apparatuses used for this type of realization. The complexity and size of the model to be printed no longer becomes a problem. In the automotive industry, for example, the technique allows the manufacture of a dashboard in one piece.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Erpro Group‘s catalogsRelated Searches

- 3D printing

- Plastic 3D printing

- Industrial 3D printing

- Prototyping 3D printing

- Medical 3D printing

- FDM 3D printing

- 3D printing for the automotive industry

- 3D printing for the aerospace industry

- Laser sintering 3D printing

- SLA 3D printing

- Resin 3D printing

- Metal 3D printing

- Polyamide 3D printing

- ABS 3D printing

- Selective Laser Melting 3D printing

- PP 3D printing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.