- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

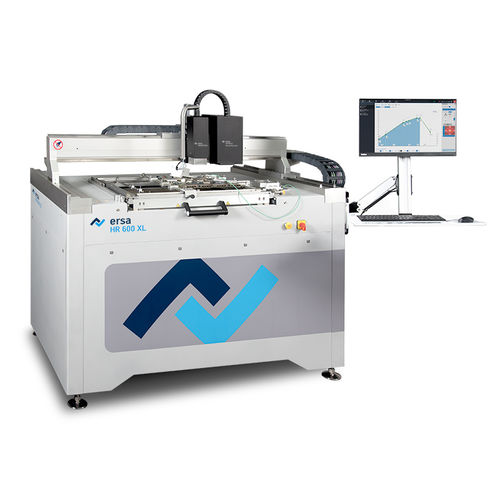

Automatic rework station HR 600XLfor SMD

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for SMD

Description

The Ersa Rework System HR 600 XL was developed for large PCB formats - components up to 60 x 60 mm can be processed just as easily as precisely. With the optionally available XL heating head, even components up to 120 x 120 mm edge length can be processed.

"Auto Scavenger" removes the residual solder automatically without any contact

After desoldering a component, any remaining solder usually has to be removed. With the "Auto Scavenger" module, there is now a fully integrated functional unit for this – immediately after removing the component, the suction nozzle of the Auto Scavenger is lowered over the circuit board and the residual solder is automatically removed without any contact.

Auto Scavenger - no set-up time!

As the Auto Scavenger is a stand-alone module, there is no set-up time for the user. The image collage opposite shows the process (from left to right) from the start with the lifting of a BGA, through the progress of the solder extraction, to the complete removal of the residual solder.

Highly efficient 800 W hybrid heating head (optional 2,000 W)

Large-area IR Matrix bottom heater with 25 single heating elements (600 W each)

Process observation with up to 8 thermocouples

Automatic and precise component alignment with the help of machine vision

Highly accurate, motor-driven axis system for component placement (+/- 0.025 mm)

User independent, reproducible repair results

Process control and documentation via the operator software HRSoft 2

Suitable for the use of the Dip&Print Station

Dimensions (W x D x H) in mm: 2250 x 1700 x 1650 incl. Monitor holder

Footprint: 1691 x 1180 mm

Antistatic Design (y/n): yes

VIDEO

Catalogs

DISCOVER-SMART-TECHNOLOGIES

8 Pages

REWORK- & INSPECTION SYSTEMS

44 Pages

Related Searches

- Ersa soldering machine

- Reflow soldering machine

- Automated soldering machine

- Ersa rework station

- Printed circuit soldering machine

- Ersa selective soldering machine

- Hot air rework station

- Ersa automatic rework station

- BGA rework station

- Ersa automatic selective soldering machine

- Ersa PCB selective soldering machine

- Vacuum soldering oven

- Ersa wave selective soldering machine

- PCB rework station

- Ersa SMD rework station

- Electronic component selective soldering machine

- Mini-wave selective soldering machine

- Inline selective soldering machine

- Soldering hot plate

- Compact selective soldering machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.