- Products

- ERWEKA

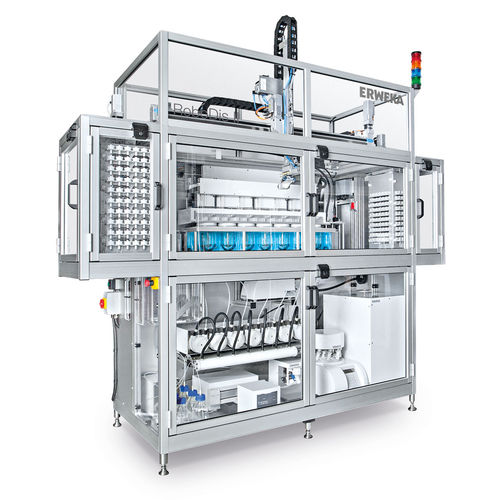

Automatic dissolution system ROBODIS II+

Add to favorites

Compare this product

Characteristics

- Type

- automatic

Description

Three complete semi-automatic dissolution testers including media preparation and vessel cleaning - this is the amount of floor space you can save with a RoboDis II+ 10-batch system, which has a footprint of no more than 2x1 m. With the RoboDis II+ the complete dissolution process can be automated. This way, fully automated testing, including setup, media preparation and automated cleaning process is possible.

RoboDis II+ is the only parallel-working, fully automated dissolution test system currently on the market. All stages of the dissolution processes are computer-controlled and therefore carried out entirely without user intervention. The key element of the fully automatic system is the Disso.NET software developed by ERWEKA, which handles all system functions, including the precise movement of the robot arm, control of the analytic devices, data processing and full documentation.

In the standard configuration, RoboDis II+ tests up to 10 batches in accordance with USP methods 1 (Basket) or 2 (Paddle). The parallel sampling approach enables very short cycle times for recording of detailed drug release profiles to be selected by the user. Integrated System Suitability Tests (SST) and video monitoring ensure a high degree of reliability. Like all ERWEKA products, RoboDis II+ is fully USP/EP/JP compliant.

RoboDis II+ for Quality control

The productivity booster

Planned productivity to suit your requirements with 10 or 40 batches

Testing non-stop: high sample volumes - 40 batches

Parallel action

Robotic precision & fault monitoring

Space-saving footprint

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.