- Products

- Catalogs

- News & Trends

- Exhibitions

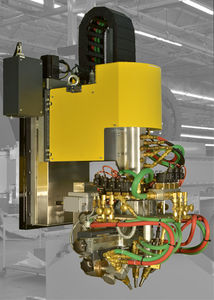

Plasma cutting head BEVEL EXCAVATOR3Dfor bevel cutting

Add to favorites

Compare this product

Characteristics

- Technology

- plasma

- Type

- 3D

- Applications

- for bevel cutting

Description

Extreme specifications call for an extraordinary cutting solution. Enter the Bevel Excavator—designed specifically for demanding bevel cuts and thick materials, up to 200 mm (8 in.). Combining 5-axis bevel motion, a heat-resistant design, and complete process integration, the Bevel Excavator not only delivers perfect cuts for intricate workpieces, but also reduces work time and costs up to 70% compared to conventional, manual processes.

Featured

Industry-leading motion technology

Featuring a supremely accurate 5-axis motion system, the Bevel Excavator produces bevel shapes that typical rotating systems can’t achieve. The torch automatically adapts to changing contours while maintaining the proper angle. Plus, the system is ruggedly designed to withstand the high heat and dust generated by oxy-fuel cutting.

Low-maintenance mechanical assembly

Automatic height control with laser sensor

Innovative torch collision protection

Advanced shielding, cooling, and sealing systems

Optimized software for optimal results

The Bevel Excavator is powered by ESAB’s sophisticated yet easy-to-use software. All complex geometrical shapes are constructed on screen based on a CAD construction. In just a few simple steps, the programmer can visualize the workpiece in 3D for quality assurance, confirm the exact tool path, and generate the part program.

Rapid import of DXF files

Intelligent algorithms save time and effort

Quick, easy selection of edges and bevels

NC program optimized for Vision CNC

VIDEO

Catalogs

No catalogs are available for this product.

See all of ESAB‘s catalogsRelated Searches

- ESAB cutting machine

- ESAB metal cutting machine

- ESAB CNC cutting machine

- Automatic cutting system

- High-speed cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- High-performance cutting system

- Compact cutting system

- Steel cutting system

- Bridge cutting system

- ESAB plasma cutting machine

- Marking cutting system

- Profile cutting center

- 3-axis cutting system

- Gantry type cutting system

- Heavy-duty cutting system

- Beveling cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.