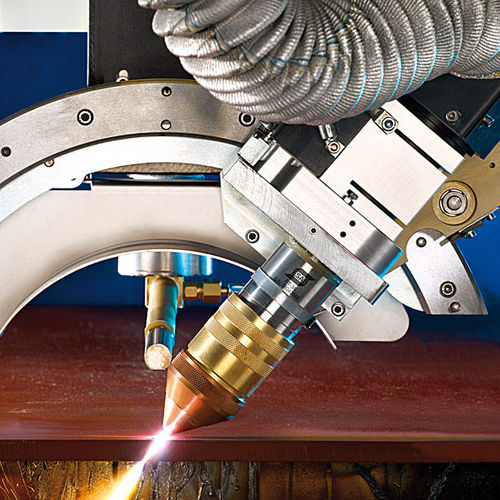

The Global PRO Variable Bevel Angle System is used to accurately plasma bevel cut plate, and is fully programmable to cut parts with both bevel and straight cuts. The system automatically switches between high accuracy tactile sensing and Smart Voltage Height Control to provide the most accurate plasma cutting, and fully program controlled, multi-part, bevel and straight cutting.

Precision machining and careful design form a durable bevel system for high production environments. The Global PRO’s natural focal point reduces machine motion, making it the ideal choice for beveling on larger gantries. The Global PRO provides reliable productivity from a well-protected, robust mechanical system.

Featured

Tactile sensor -the only system capable of precisely maintaining torch height relative to the plate surface.

Simple, reliable protractor based design automatically puts the torch tip at the focal point of tilt and rotation.

Provides "X", "V", "Y", and "K" bevel cutting with variable bevel angle on-the-fly and bevel cuts up to 45 degrees

Capable of high quality hole cutting with Precision Hole Technology™ when vertical cutting.

Capable of plasma bevel cutting dry or under water with an optional Air Curtain.

Industries

General Manufacturing

Heavy Fabrication

Marine and Offshore

Steel Cutting Centres

Tank and Vessel Fabrication

Power Poles

Windtower