- Products

- Catalogs

- News & Trends

- Exhibitions

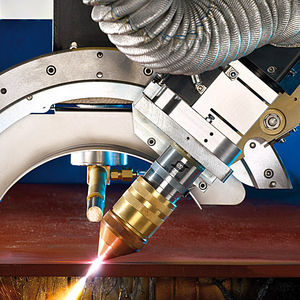

Plasma cutting machine VBA-Wrist™for metaltubeprofile

Add to favorites

Compare this product

Characteristics

- Technology

- plasma

- Material

- for metal

- Product handled

- tube, profile

- Control type

- CNC

- Associated function

- chamfering

- Configuration

- compact

- Other characteristics

- 3D

Description

ESAB's VBA Wrist is the best solution for automated 3D cutting on heavy pipe, tube, and dome applications. Available with either plasma or oxy-fuel cutting torches, the VBA Wrist can produce continuously variable bevel cuts allowing for perfect fit up and optimum weld joint geometry. Structural steel and vessel fabricators around the world rely on the VBA Wrist to cut cost, improve accuracy, and enhance safety in the most demanding 3D cutting applications.

The unique motion system of the VBA Wrist allows it to reach further down on tank heads or domes without interference, making it the best solution for automated weld-joint bevel cutting of dome penetrations. The VBA Wrist ensures years of reliable operation through a simple, durable mechanical design that is well protected from the harsh thermal cutting environment.

Featured

Optimized motion system allows wide range of angles with minimum chance of collision with domes

Longer vertical reach to handle more 3D applications, handle larger domes and pipes with customized vertical lifters

Eliminates manual layout and manual cutting

Automates weld preparation, dramatically reducing manual grinding to add bevels

Available for plasma or oxy-fuel cutting to handle any wall thickness

Automatic centering system for domes

Significantly reduces material handling

Industries

Heavy Fabrication

Marine and Offshore

Power Poles

Structural Steel Fabrication

Tank and Vessel Fabrication

Windtower

VIDEO

Catalogs

No catalogs are available for this product.

See all of ESAB‘s catalogsRelated Searches

- ESAB cutting machine

- ESAB metal cutting machine

- ESAB CNC cutting machine

- Automatic cutting system

- High-speed cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- High-performance cutting system

- Compact cutting system

- Steel cutting system

- Bridge cutting system

- ESAB plasma cutting machine

- Marking cutting system

- Profile cutting center

- 3-axis cutting system

- Gantry type cutting system

- Heavy-duty cutting system

- Beveling cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.