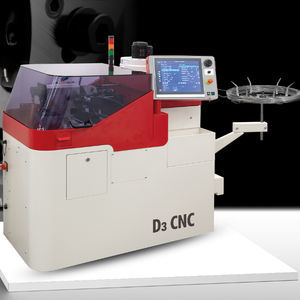

CNC automatic lathe D2/D52-axis2-spindlefor small workpieces

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis

- Number of spindles

- 2-spindle

- Applications

- drilling, for large-diameter parts, for small workpieces

- Performance

- precision, high-productivity

- Associated function

- tapping, threading

- Diameter

Max.: 4 mm

(0.16 in)Min.: 0.3 mm

(0.01 in)- Spindle speed

Max.: 18,000 rpm

(113,097.336 rad.min-1)Min.: 600 rpm

(3,769.911 rad.min-1)- Maximum part length

80 mm

(3 in)- Nominal power

4 kVA

(5.4 hp)- Coolant capacity

80 l

(21 gal)- Overall lenght

1,360 mm

(54 in)- Overall width

750 mm

(30 in)- Overall height

1,560 mm

(61 in)- Weight

850 kg

(1,874 lb)

Description

The escomatic D2 is the revolutionary and innovative evolution of the fastest automatic turning machine for precise and economic manufacturing of simple parts up to 4.0 mm diameter in large and small lot sizes.

The basis of the escomatic D5 is identical with the one of the escomatic D2. Machine base, straightening unit, feed system and rotating tool head are absolutely identical with the D2. On the escomatic D5 the counter collet of the D2 has been replaced by a system for the front machining which consists of a cross table with 2 axes supporting 2 drilling spindles, one threading/tapping spindle and one counter collet with programmable positioning.

The CNC control allows for flexible and optimized manufacturing of turned parts without cycle time loss. The advantages of cam driven machines are maintained. The very simple programming system which is based on the experience of operators allows all operators to learn to operate and program the machine within a few hours.

Application Profile

Turning operations with two cutting tools

Machining from coil for 24 hours production

Features

Menu guided programming / set-up and quick process adaption

escomatic standard turning tools can be used

Fast cycles and short machining times at enhanced precision

Best price / performance ratio for the production of parts with small diameters

Improved parts quality, both in meeting tolerances and in surface finish

Reduction of labour costs due to fewer machine stops by using material from coil, real 24h operation

Economy of floor space due to compact design of the unit “machine & coil stand”

Easy and simple set up and operation due to the absence of cams

VIDEO

Catalogs

No catalogs are available for this product.

See all of ESCO S.A.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.