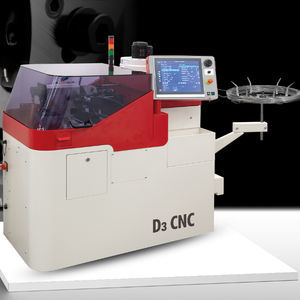

CNC automatic lathe NM8 FLEXI3-spindle4 toolsfor large-diameter parts

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of spindles

- 3-spindle

- Number of tool stations

- 4 tools

- Applications

- for complex parts, for large-diameter parts

- Performance

- high-speed, powerful

- Associated function

- tapping, drilling

- Diameter

8 mm

(0.31 in)- Spindle speed

4,000 rpm, 8,000 rpm, 15,000 rpm

(25,132.741 rad.min-1, 50,265.482 rad.min-1, 94,247.78 rad.min-1)- Maximum part length

150 mm

(6 in)- Nominal power

8 kVA

(10.9 hp)- Coolant capacity

200 l

(53 gal)- Overall lenght

2,800 mm

(110 in)- Overall width

1,650 mm

(65 in)- Overall height

1,850 mm

(73 in)- Weight

1,800 kg

(3,968 lb)

Description

The NM8 FLEXI machine incorporates all the concepts of the NM6 FLEXI machine that have made this lathe one of the most efficient products on the market.

To meet the constraints of machining larger diameters, we have developed the following specific elements:

Two CNC axes for the management of turning tools, which allows to 2 cutting tools to work simultaneously

New material straightening device ensures high quality straightening up to 8mm

As the NM6 FLEXI machines, the use of two completely independent cross tables allows to work on secondary operations on 2 parts at the same time: one part machined in the turning and front operation while the second parts positioned in the counter spindle is machined at the rear.

The material can be loaded in form of coil up to a diameter of 8 mm. It will then be transformed into bar stock material after the rotating straightening process.

The machine has been configured so that it is possible to remove the straightening unit and equip the machine with bar loader.

APPLICATION PROFILE

Average to high parts volume

Very short cycle times

24 hours production

Simple to medium complexity parts

FEATURES

Two cutting tools can work simultaneously

Choice of escomatic cutting tools or inserts from other suppliers

High speed manufacturing thanks to the independent front and rear machining units permitting to work on 2 parts simultaneously

Flexibility of the straightening thanks to its’ electric drive and programming from the console

Improved quality of straightening by control over the rotating and traversing speed

Easy access for the operator granted by the complete opening of the frontal guarding

Catalogs

No catalogs are available for this product.

See all of ESCO S.A.‘s catalogsRelated Searches

- Automatic lathe

- CNC automatic lathe

- Multi-spindle Swiss lathe

- High-productivity automatic lathe

- Drilling automatic lathe

- Drilling Swiss lathe

- Tapping automatic lathe

- 2-spindle automatic lathe

- 4 tools automatic lathe

- Precision automatic lathe

- Powerful Swiss lathe

- 2-axis automatic lathe

- High-performance automatic lathe

- High-speed automatic lathe

- Compact automatic lathe

- 10-axis Swiss lathe

- 8-axis Swiss lathe

- Complex part Swiss lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.