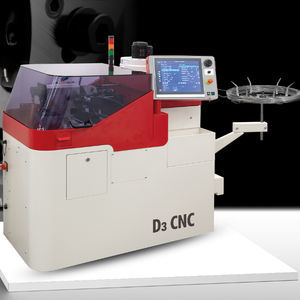

CNC automatic lathe D5-D6 TWIN10-axis8-axis3-spindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 10-axis, 8-axis

- Number of spindles

- 3-spindle

- Performance

- high-productivity

- Diameter

Min.: 0.3 mm

(0.01 in)Max.: 4 mm

(0.16 in)- Spindle speed

Min.: 603 rpm

(3,788.761 rad.min-1)Max.: 18,000 rpm

(113,097.336 rad.min-1)- Maximum part length

80 mm

(3 in)- Rapids on Z

8 m/min

- Nominal power

4 kVA

(5.4 hp)- Coolant capacity

100 l

(26 gal)- Overall lenght

2,150 mm

(85 in)- Overall width

1,050 mm

(41 in)- Overall height

1,580 mm

(62 in)- Weight

1,150 kg

(2,535 lb)

Description

THREE TURNING TOOLS FOR MORE PRODUCTIVITY AND FLEXIBILITY

The escomatic D5-D6 TWIN has been designed to revolutionise production. The rotating toolhead, rotating at 12,000 rpm, has 2 or 3 cutting tools that can be controlled separately, depending on your requirements, for greater flexibility and simplification of the process. The cut part can be machined simultaneously on 2 counter operations (DUAL double machining system). The 2 counter-spindles equipped with a C axis are each mounted on a table equipped with separate CNC axes with a travel of 40m/minute. The rear of the part can be machined by 3 axial spindles and 1 transverse spindle at a speed of 18,000 rpm, for high-performance secondary machining operations. All this is supported by a new 3-channel Pegasus/Beckhoff CNC control dedicated specifically to the machine, for greater flexibility and ease of use.

Application profile

Parts turned and machined on one side only, requiring

very short cycle times

Maximum number of operations on a single machine

Machining from coils with real work 24-hour continuous

Catalogs

No catalogs are available for this product.

See all of ESCO S.A.‘s catalogsRelated Searches

- Automatic lathe

- CNC automatic lathe

- Multi-spindle Swiss lathe

- High-productivity automatic lathe

- Drilling automatic lathe

- Drilling Swiss lathe

- Tapping automatic lathe

- 2-spindle automatic lathe

- 4 tools automatic lathe

- Precision automatic lathe

- Powerful Swiss lathe

- 2-axis automatic lathe

- High-performance automatic lathe

- High-speed automatic lathe

- Compact automatic lathe

- 10-axis Swiss lathe

- 8-axis Swiss lathe

- Complex part Swiss lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.