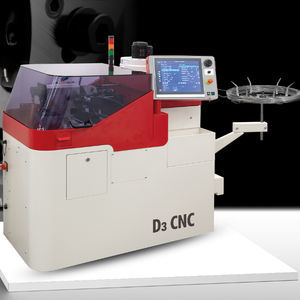

CNC automatic lathe NM6 FLEXI3-spindle4 toolsprecision

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of spindles

- 3-spindle

- Number of tool stations

- 4 tools

- Performance

- precision, high-performance

- Associated function

- tapping, drilling

- Diameter

6.5 mm

(0.26 in)- Spindle speed

10,000 rpm, 12,000 rpm, 15,000 rpm

(62,831.853 rad.min-1, 75,398.224 rad.min-1, 94,247.78 rad.min-1)- Maximum part length

150 mm

(6 in)- Nominal power

8 kVA

(10.9 hp)- Coolant capacity

130 l

(34 gal)- Overall lenght

2,270 mm

(89 in)- Overall width

1,600 mm

(63 in)- Overall height

1,700 mm

(67 in)- Weight

1,600 kg

(3,527 lb)

Description

The escomatic NM6 Flexi takes its place in the center of the ESCO SA range between the Dx CNC (escomatic D2 / D5 CNC, D5 ULTRA, D5 TWIN) and the NM8 FLEXI. It will succeed the New Mach 64x range which has held a successful position for many years. More than an evolution of the New Mach 64x.

Two rules have availed for the development:

Take the best elements of the previous New Mach 64x range to ensure its best starting quality.

Integrate the latest Esco development skills with the latest available technologies to make it more flexible, faster and cheaper.

The escomatic NM6 Flexi took over the high-performance tool head of the New Mach range as working base.

THE MAJOR INNOVATION

Two completely independent secondary slides, which allows work on secondary operations from the front and back in a much more efficient way than on the current range.

OTHER INNOVATIONSManagement by ball screw drive and programming from the console for an optimized straightening

Integration of measure scales on the secondary slides which will guarantee the precision of positioning

Easy access for the operator granted by the complete opening of the frontal protection

ADVANTAGES

More flexible, thanks to the possibility to program the secondary slides independently and because the straightening can be controlled and adjusted from the console.

Easier, through a wide-open access for the operator and the use of the latest programming technologies FANUC 0i-TF.

Faster, because the independent functioning of the two front and back units will ensure for improved cycle times

Catalogs

NM6 Flexi

2 Pages

Related Searches

- Automatic lathe

- CNC automatic lathe

- Multi-spindle Swiss lathe

- High-productivity automatic lathe

- Drilling automatic lathe

- Drilling Swiss lathe

- Tapping automatic lathe

- 2-spindle automatic lathe

- 4 tools automatic lathe

- Precision automatic lathe

- Powerful Swiss lathe

- 2-axis automatic lathe

- High-performance automatic lathe

- High-speed automatic lathe

- Compact automatic lathe

- 10-axis Swiss lathe

- 8-axis Swiss lathe

- Complex part Swiss lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.