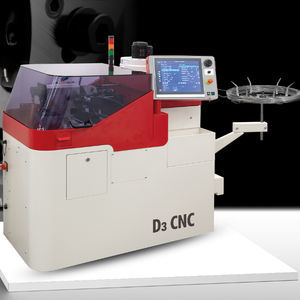

CNC automatic lathe NM6 TWIN3-spindle4 toolshigh-performance

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of spindles

- 3-spindle

- Number of tool stations

- 4 tools

- Performance

- high-performance

- Associated function

- tapping, threading, drilling

- Diameter

6.5 mm

(0.26 in)- Spindle speed

1,000 rpm, 12,000 rpm, 15,000 rpm

(6,283.185 rad.min-1, 75,398.224 rad.min-1, 94,247.78 rad.min-1)- Nominal power

8 kVA

(10.9 hp)- Coolant capacity

130 l

(34 gal)- Overall lenght

2,650 mm

(104 in)- Overall width

1,650 mm

(65 in)- Overall height

1,850 mm

(73 in)- Weight

1,800 kg

(3,968 lb)

Description

More Flexible, more versatile, faster

Thanks to the new design and to the use of two completely independent cross tables for the front and back machining units, the NM6 TWIN breaks the limits of flexibility and performance.

Secondary operations could be carried out with 2 identical units consisting of:

2 counter collet spindles with C-axis which are mounted on 2 independent tables with cross slides;

2 back machining units which are equipped with 4 axial fix toolholders or 4 axial spindles for drilling, tapping or threading and 1 cross spindle.

This configuration doubles the back machining operations and 3 parts are machined simultaneously.

Catalogs

No catalogs are available for this product.

See all of ESCO S.A.‘s catalogsRelated Searches

- Automatic lathe

- CNC automatic lathe

- Multi-spindle Swiss lathe

- High-productivity automatic lathe

- Drilling automatic lathe

- Drilling Swiss lathe

- Tapping automatic lathe

- 2-spindle automatic lathe

- 4 tools automatic lathe

- Precision automatic lathe

- Powerful Swiss lathe

- 2-axis automatic lathe

- High-performance automatic lathe

- High-speed automatic lathe

- Compact automatic lathe

- 10-axis Swiss lathe

- 8-axis Swiss lathe

- Complex part Swiss lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.