ESPRIT offers a powerful suite of multi-axis probing cycles for any combination of CNC machine, control, and touch probe manufacturer. ESPRIT Multi-Axis 3+2 probing cycles may be added at any point during the part program and combined with other ESPRIT cycles into one complete part program to support all machining and on-machine inspection needs. Using the ESPRIT Digital Machine, probing cycles are automatically chosen based upon the part geometry selected for inspection. Simulation is performed prior to machining to verify the probing in combination with all other machining processes. Finally, edit-free G-code is generated to activate the corresponding probing cycles embedded in the physical machine's control.

A powerful suite of probing cycles

Naturally integrated into the ESPRIT workflow

Universally available for any CNC machine, control, and touch probe

Combining machining and inspection into one complete program

Workpiece Location

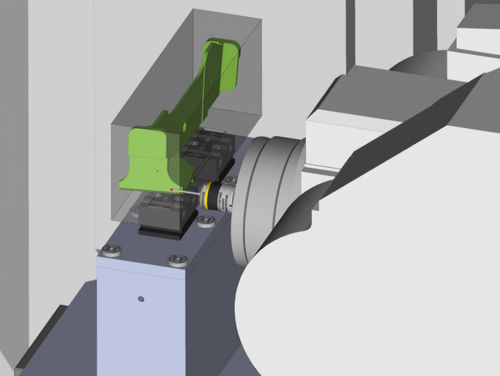

ESPRIT's multi-axis probing cycles may be used on the stock or workpiece to dynamically update work offsets, which then provide accurate data to be used for subsequent machining operations. In this scenario, when material is loaded, new datum points are established for the stock’s exact location, accounting for variances in the workholding and part loading. For parts with varying stock, such as castings and forgings, ESPRIT's probing cycles are used to establish accurate datum points and alignment to ensure the subsequent machining processes are adapted to variations in stock conditions.