- Robotics - Automation - Industrial IT

- Industrial Software

- CAM software

- ESPRIT by DP Technology

CAM software SolidMill FreeForm™programmingconfigurationfor cutting machine

Add to favorites

Compare this product

Characteristics

- Function

- programming, configuration, CAM

- Applications

- 3-axis machining, 3-axis machining, for cutting machine

- Type

- 3D

- Other characteristics

- high-performance

Description

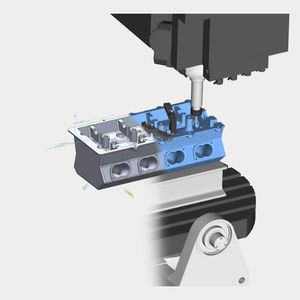

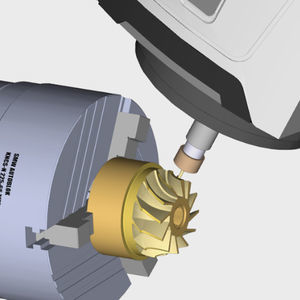

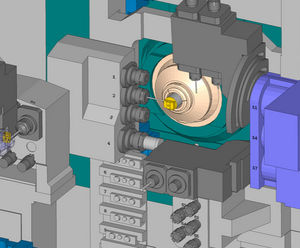

ESPRIT offers a powerful suite of 3-axis machining cycles for roughing, prefinishing, finishing, and remachining of complex freeform parts. ESPRIT SolidMill FreeForm™ is extensively used by customers in mold and die, tool making, discrete parts, and model-making markets. Each of ESPRIT’s 3-axis machining cycles are optimized for machining 3D models that may include surfaces, solids, and STL geometry. With ESPRIT’s Modeless Programming™, the FreeForm cycles may be used on any configuration of mill, lathe, mill-turn, and Swiss-type machine. These 3-axis cycles may also be combined within any other ESPRIT cycle to create one complete part program for the entire part.

A powerful suite of 3-axis cycles for machining complex freeform parts, used by customers in mold and die, tool making, discrete parts, and model-making markets

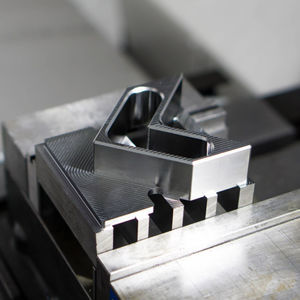

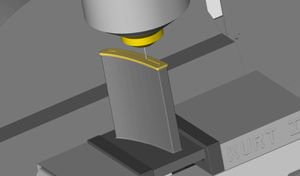

High-Performance Roughing

ESPRIT’s roughing cycles will machine workpieces down to a near net shape using the highest possible material removal rates, resulting in the shortest cycle times. ProfitMilling does this by maintaining a consistent tool engagement angle, chip load, lateral cutter force, and machine acceleration to achieve optimal results.

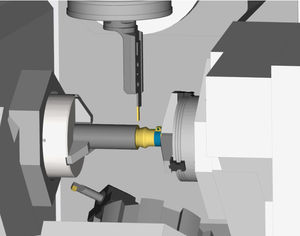

Prefinishing

Following roughing, ESPRIT has a variety of prefinishing cycles available to ensure the varying surfaces of the workpiece all have the exact required stock allowance. As a result, the finishing tool or tools have a constant volume of material to remove, resulting in maximizing tool life and optimal surface finishes.

Catalogs

No catalogs are available for this product.

See all of ESPRIT by DP Technology‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Computer-aided design software

- Control software solution

- 3D software solution

- Industrial software solution

- Simulation software

- Programming software

- Machine software

- EDM software

- 2D software

- Optimization software solution

- Planning software

- Calculation software

- High-performance software solution

- CAM software

- Inspection software

- CAD/CAM software

- Milling software

- Embedded software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.