- Robotics - Automation - Industrial IT

- Industrial Software

- CAM software

- ESPRIT by DP Technology

CAM software ProfitMilling®programmingfor cutting machine2-5 axis machining

Add to favorites

Compare this product

Characteristics

- Function

- programming, CAM

- Applications

- for machine tools, 2-5 axis machining, for cutting machine

Description

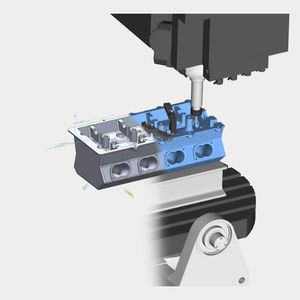

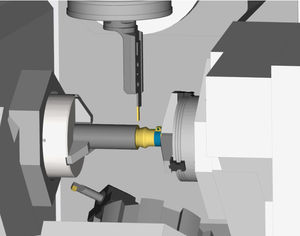

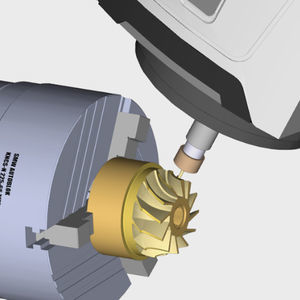

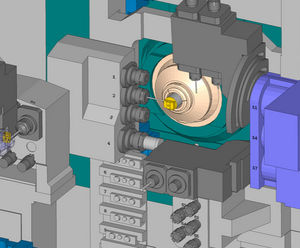

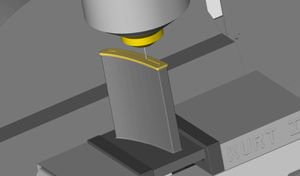

High-speed machining with ESPRIT’s patented ProfitMilling® cycles for 2.5-, 3-, 4-, and 5-axis roughing significantly reduces cycle times and dramatically increases tool life. The ProfitMilling strategy combines optimized, high-speed toolpath patterns, chip thinning with light radial engagements and full depths of cut, and dynamically optimized feed rates to maintain consistent chip loads and minimized cutting forces throughout the cut. This results in increased productivity and reduced operating costs. When compared to conventional machining, ProfitMilling delivers:

75% cycle-time reduction

500% increase in tool life

ProfitMilling Benefits

ProfitMilling is a universal high-speed roughing cycle for 2- to 5-axis milling that requires no extra investments in specialized cutting tools, workholding, spindles, or machines. This cycle is designed to reduce loads on CNC machines, drives, and spindles, therefore it can even be used on light-duty machines. ProfitMilling is proven to work exceptionally well on most materials, with added value in Inconel, titanium, and others where the chip is hard to break. The combination of optimized toolpaths cutting at full depth with reduced radial engagement results in improved cutting performance and shorter cycle times. These techniques also transfer more heat to the chip instead of the tool and the workpiece, reducing the temperature at the cutting zone and extending tool life.

High-speed machining for 2.5-, 3-, 4-, and 5-axis roughing

Productivity improvements even with light- and medium-duty machine tools

Catalogs

No catalogs are available for this product.

See all of ESPRIT by DP Technology‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Computer-aided design software

- Control software solution

- 3D software solution

- Industrial software solution

- Simulation software

- Programming software

- Machine software

- EDM software

- 2D software

- Optimization software solution

- Planning software

- Calculation software

- High-performance software solution

- CAM software

- Inspection software

- CAD/CAM software

- Milling software

- Embedded software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.