- Products

- Catalogs

- News & Trends

- Exhibitions

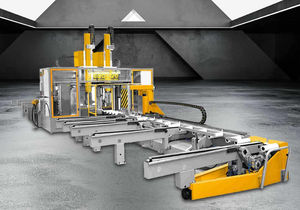

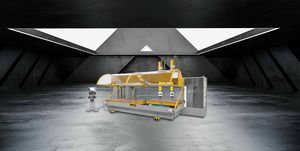

Automatic edge-banding machine Fusion for woodfor pre-glued bands

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for wood, for pre-glued bands

Description

Fusion is the answer to the market’s production requirements for flexible and versatile manufacturing of furniture components, tops, shelves, doors and tables; obtained from bars.

Unlike the traditional system which requires a bar cutter, edgebander or square-edgebanding to perform these processes, Fusion concentrates all the technologies in a single working centre, thus doubling production in half the space.

The result is a future-oriented and ultra-modern production line thanks to the application of the most advanced technologies.

WORKING UNITS

Fusion cuts and edgebands the panels by combining the well-proven cutting and edgebanding systems with a new blade and scoring unit and two NC- controlled spindle moulder units to achieve a finished and précisé eut.

GLUING UNIT

The working centre is equipped with the latest edgebanding capabilities, with a glue application unit for edges up to 80 mm thickness- the glue applied is either polyurethane or pre-melt types.

EDGETRIMMING

For effective edge trimming, the machine uses a revolverhead with 4 trimmers using copying devices. NC of the copying devices guides the panel's profile accurately, this ensures quality results on a variety of edge materials including melamine, laminate, ABS, unicolorand so forth.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Essetre‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.