- Products

- Catalogs

- News & Trends

- Exhibitions

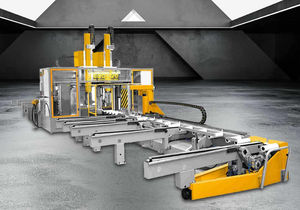

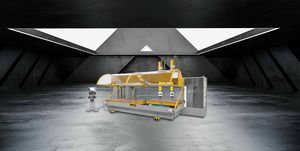

Automatic edge-banding machine FUSION LONGfor woodfor pre-glued bands

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for wood, for pre-glued bands

Description

Fusion Long is a working centre covered by international patents to simultaneously section and edgeband the elements longitudinally in the required widths. Fusion Long needs reduced spaces and allows fully automated in-line production, without needing the presence of operators; thus revolutionising and complementing the traditional system which is 6 x more bulky.

WORKING UNITS

Sawing and edgebanding thanks to a new unit consisting of a double blade with engraver. In addition to this unit, there are two spindle moulder units controlled by the NC, in order to obtain a finished and précisé eut.

GLUING UNIT

Gluing unit for edges up to 80mm high with availability of melting and polyurethanic glue tanks and the relating pre melting devices. The finishing of the various edge thicknesses is guaranteed thanks to trimming units provided with copying devices which are managed by the NC and follow precisely the bar's profile, obtaining in this way the best results on edges of each material- for example melamine paper, laminate, ABS and more.

CLAMPING UNIT

High-precisionworkpiece clamping unit controlled by the NC for automatic adjustment of the cutting width.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Essetre‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.