- Products

- Catalogs

- News & Trends

- Exhibitions

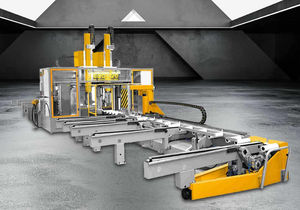

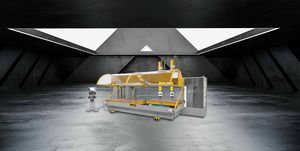

3-axis CNC machining center Power Top6-axisverticalfor wood

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis, 6-axis

- Spindle orientation

- vertical

- Machined material

- for wood

- Number of tool stations

- 11 tools

- Associated functions

- milling

- Applications

- for panels

- X travel

4,300 mm

(169.29 in)- Y travel

1,200 mm

(47.24 in)- Z travel

250 mm

(9.84 in)- Rotational speed

Min.: 1,000 rpm

(6,283 rad.min-1)Max.: 18,000 rpm

(113,097 rad.min-1)- Power

12 kW, 22 kW

(16.32 hp, 29.91 hp)- Weight

13,500 kg

(29,762.41 lb)

Description

Power Top allows the simultaneous processing of the top and the bottom faces of the panel, thanks to the two independent and opposing milling heads (one superior and one inferior). This system considerably improves and speeds up all the in-line processings of the panel.

MILLING UNITS

2 opposing independent 3-axis milling units with 12 kW motor and with liquid cooling.

TOOL CHANGER MAGAZINE

Automatic tool- changer magazine with 11 positions.

PROCESSINGS

Possibility to work the upper lower side of the panel simultaneously, thanks to two independentand opposite milling heads(one upper and one lower).

WORKING AREA

The patented working area prevents the chips accumulation and does not need any maintenance and operator's presence. The rear guide is fixed, while the front guide is managed by the NC and opens and closes automatically, according to the single panel's depth. The panel's clamping guides are composed of motorized rollers(Essetre Essetre), which allow both the movement of the panels inside the working area and their exit. The rollers appear and disappear automatically in order to allow the passage of the milling tools during the processing.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Essetre‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- Machining center for the automobile industry

- Wood CNC machining center

- Machining center for the aeronautical industry

- CE CNC machining center

- HSK F63 CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.