- Products

- Catalogs

- News & Trends

- Exhibitions

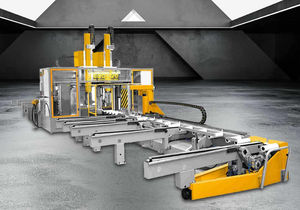

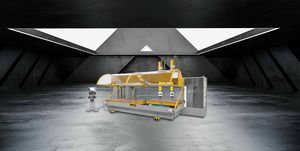

5-axis CNC machining center Techno SAW6-axisverticalfor wood

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis, 6-axis

- Spindle orientation

- vertical

- Machined material

- for wood

- Spindle mount

- HSK F63

- Number of tool stations

- 8 tools

- Other characteristics

- compact

- X travel

750 mm

(29.53 in)- Z travel

550 mm

(21.65 in)

Description

NC working centre to cut and process trusses, elements of frame houses, light and solid wood beams. Maximum working section 450 x h 150 mm.

MILLING HEAD

Patented milling head with 5 continuous

interpolating axis for the processing of the 6 faces

of the workpiece. Patented dual output motor with

HSK63F tool holder.

LOADING AREA

Additional loading area to process workpieces up to 13000 mm, consisting of 5 fixed supports on the machine structure equipped with motorized chains for the automatic loading of boards and beams on the loose rollers of the machine entry plan.

AUTOMATIC CLAMP

Automatic clamp controlled by NC upon linear guides movement.

TOOL MAGAZINE

Rotative tool changing magazine with 8 positions for HSK63F cônes, managed by a controlled axis. The magazine is installed on the front of the cabin, complété with automatic cover to keep cônes and toolsclean.

CONSOLE

The control console complété with NC is installed on the machine structure through a hinge system, which allows it to be oriented in multiple positions. A remote control panel is available complété with manual Controls of the axis movement, START, STOP and RESET of the program.

E-LIVE SOFTWARE

The machine is controlled by the new Essetre E- Live Software with three-dimensional display of the workpiece and relative processing. Its versatility allows it to interface with the most well-known Cad Cam programs specific for wooden structures. The software is also equipped with a simulation and anti-collision system.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Essetre‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- Machining center for the automobile industry

- Wood CNC machining center

- Machining center for the aeronautical industry

- CE CNC machining center

- HSK F63 CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.