- Machine-tools

- Machine Tool Accessory

- Touch screen CNC controller

- ESTUN Automation Co., Ltd.

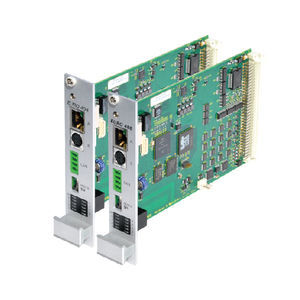

Shearing machine CNC controller DAC360Ttouch screen

Add to favorites

Compare this product

Characteristics

- Applications

- for shearing machine

- Other characteristics

- touch screen

Description

•Installation as panel

•High-brightness lcd display

•Back/front gauge control

•Concession function

•Shear angle and gap control

•Shear stroke limitation

•Ail axes can be jogging

•(DAC-362T)

•Sheet support function

•Pressure control

•Plate thickness détection

•Return to feeding position function

•Second and third servo axis control

I The DAC-360T control unit provides an easy-to-operate and versatile solution for shearing machines.

Based on the latest electronic technology, multiple backgauge axes, shearing angle, shearing length and blade gap control can be provided according to customer needs.

I Except backgauge control, DAC-360T can automatically calculate the required shear angle and gap values based on material properties and thickness. The shearing stroke can be automatically optimized

based on the length of the sheared sheet to increase production efficiency.

I Servo system and VFD can be used as the control of backgauge. Bilatéral positioning or unilatéral positioning can be chosen for specific application, and using the optional screw correction table function.

DAC-362T supports two and three gauge axis Controls, providing control of additional gauges and related functions. Ail clamping and shearing pressures can be effectively controlled on the DAC-360T.

I The bright LCD display and easy-to-operate touch screen make the opération very convenient and easy for users. Operators can easily complété ail functions of data programming by relying on clear instructions.

Catalogs

No catalogs are available for this product.

See all of ESTUN Automation Co., Ltd.‘s catalogsOther ESTUN Automation Co., Ltd. products

Motion control system

Related Searches

- Human machine interface

- HMI with touch screen

- Panel-mount human machine interface

- Ethernet human machine interface

- USB human machine interface

- Industrial human machine interface

- Estun Automation CNC controller

- Wireless HMI

- Touch screen numerical control

- IoT HMI

- WiFi human machine interface

- Compact CNC controller

- ARM Cortex HMI

- Economical HMI

- 4G HMI

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.