- Robotics - Automation - Industrial IT

- Industrial Software

- Control software

- ETAP (IGE) / IGE+XAO

Test software SIMACanalysismonitoringsimulation

Add to favorites

Compare this product

Characteristics

- Function

- test, analysis, monitoring, simulation, programming, modeling, quality, control, HMI, electrical CAD, creation, commissioning, training

- Applications

- process, machine, PLC, architecture, flow, mechanical

- Type

- 3D

Description

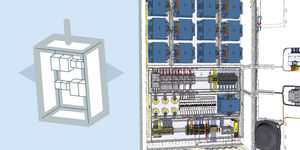

SIMAC is a machine or process simulator. It allows the creation of virtual facilities, which connect to the actual control systems architecture. The objective is to test and validate the control-command before the actual commissioning on site.

How it works

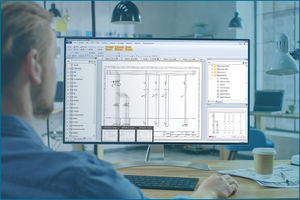

The first step consists in modeling the equipment to be simulated. This model is very detailed and very objective. The user describes in SIMAC all electrical equipment, PLC input and outputs devices, all this coming from the electrical CAD tool. Are also described in SIMAC mechanical equipment, movements and their speed, sensors, energy requirements … The flow of parts or products are described as well as all facility physical quantities that will test the control and monitoring system.

These mechanical, physical and electrical data are represented using SIMAC synoptic. These views allow the user to interact with the model. A 3D representation has been added to SIMAC in order to increase the realism of the simulation. This 3D application is directly controlled by the SIMAC model.

The user has during the simulation a large number of tools that allow him to control his machine using panels with push buttons, switches, but also scenarios tools that allow him to record and replay sequences, traps or context analysis tools to easily detect command-control behavior anomalies, that will be corrected with the software programming workshop.

SIMAC is a tool for PLC programs and HMI validation. Time and quality savings at commissioning are very important. SIMAC is also a training tool: it allows operators and maintenance personnel to take charge of the equipment prior to commissioning.

Catalogs

No catalogs are available for this product.

See all of ETAP (IGE) / IGE+XAO‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Control software solution

- Computer-aided design software

- Real-time software solution

- Online software

- Design software solution

- 3D software solution

- Monitoring software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Programming software

- Automated software

- Development software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.