- Robotics - Automation - Industrial IT

- Industrial Software

- Management software

- ETAP (IGE) / IGE+XAO

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Management software SEE Electrical Harness Manufacturingengineeringtestinspection

Add to favorites

Compare this product

Characteristics

- Function

- management, engineering, test, inspection, tracing, manufacturing execution system

- Applications

- process

- Type

- automated

- Operating system

- Windows, Android

Description

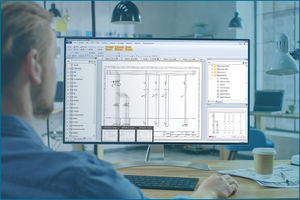

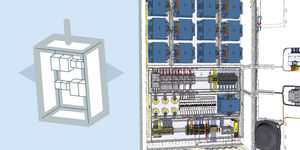

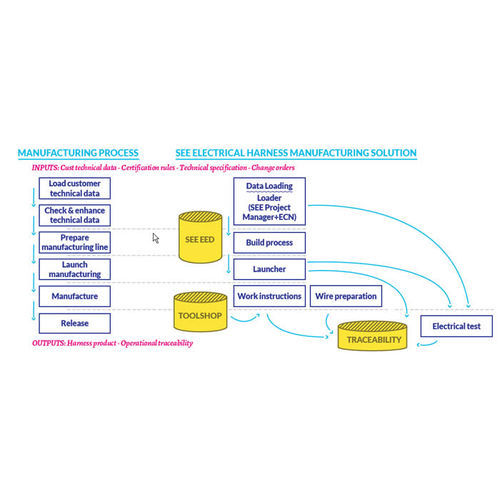

Manufacturing engineering phase

Starting with data representing the physical harness (eg. customer data in XML format), this set of tools will prepare harness manufacturing data. First step is to load the data (effectivity and legacy management). Then, ECN applies automated changes, executes custom rules and checks physical harness data. Hence, Build process assigns operations and tools, sorts wires and assigns the different helps. The output is an industrialized harness.

Production phase

Launcher generates the manufacturing harness by worksite as well as the differential.

A set of independent modules provides added features

Wire preparation: creates production batches, assigns machines and printers, cuts cables/protections and prints labels.

Work instructions: designs templates and generates static instructions as well as interactive instructions (Apple, Android or Windows apps).

Test: assigns mating and interfaces, calculates functional lines, maps addresses and generates tester code.

Traceability: stores production traceability, validates harness production and provides after-delivery inspection.

Toolshop: manages tools, tools revisions and tools authorizations.

Workers and Skills: manages operators as well as skills and trainings.

Catalogs

No catalogs are available for this product.

See all of ETAP (IGE) / IGE+XAO‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Windows software solution

- Control software solution

- Online software

- Real-time software solution

- Design software solution

- 3D software solution

- Monitoring software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Programming software

- Automated software

- Development software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.