- Products

- Catalogs

- News & Trends

- Exhibitions

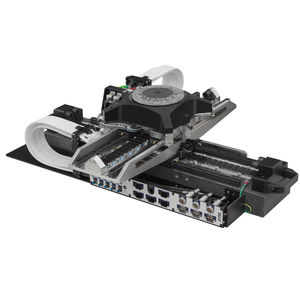

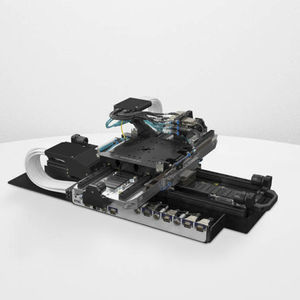

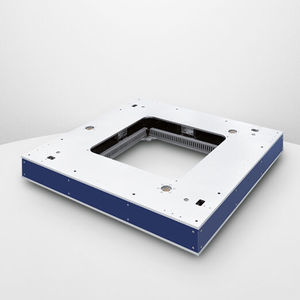

Linear positioning stage METISmotorized2-axisair bearing

Add to favorites

Compare this product

Characteristics

- Orientation

- linear

- Type

- motorized

- Number of axes

- 2-axis

- Other characteristics

- high-precision, air bearing

- Stroke

Min.: 12 mm

(0.472 in)Max.: 321 mm

(12.638 in)- Speed

0.02 m/s, 0.1 m/s, 1.2 m/s

(0.07 ft/s, 0.33 ft/s, 3.94 ft/s)- Repeatability

0.25 µm, 0.3 µm, 0.4 µm

- Load

625 kg

(1,377.89 lb)

Description

Introducing METIS, a state-of-the-art hybrid planar mechanical/air bearing platform designed for step and scan applications, ensuring unparalleled accuracy, move & settle times and speed stability over 4 degrees of freedom.

The METIS platform is a cutting-edge hybrid planar mechanical/air bearing platform, dedicated to step and scan applications with four-axis movement in X, Y, Z, and Theta directions. Its dynamic flatness over the full travel range and bidirectional repeatability make it ideal for high-precision tasks. METIS is widely used in Wafer Process Control applications such as Critical Dimension and Thin Film Metrology, Wafer Scribing, and Wafer Laser Thermal Annealing. It is also suitable for Back End Of Line Lithography machines (mask aligners) and some wafer dicing applications.

METIS delivers reliable performance, making it an essential tool for advanced semiconductor and photonics applications.

Characteristics

METIS combines mechanical and air bearing technologies for ultimate precision and flexibility.

METIS enables movements in X, Y, Z, and Theta axes, ideal for step and scan applications.

The platform offers high dynamic flatness and high bidirectional repeatability over the entire travel range.

METIS is used in wafer process control, wafer scribing, and laser thermal annealing.

The platform delivers reliable performance for advanced semiconductor and photonics applications.

METIS is also suitable for back-end lithography machines and wafer dicing applications.

Here are the key features of our models:

Flatness of motion

Maintained by air bearing technology over the full travel range.

Catalogs

Related Searches

- Actuator

- Linear actuator

- Stage

- Electric actuator

- Linear stage

- Motorized stage

- Compact actuator

- DC actuator

- Linear unit

- Precision actuator

- 2-axis stage

- Anodized aluminum actuator

- Electric linear unit

- High-accuracy stage

- Mini actuator

- Precision linear unit

- Linear positioning system

- High-performance actuator

- Screw linear unit

- 3-axis positioning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.