- Products

- Catalogs

- News & Trends

- Exhibitions

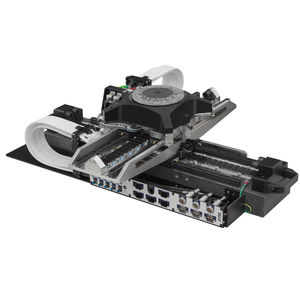

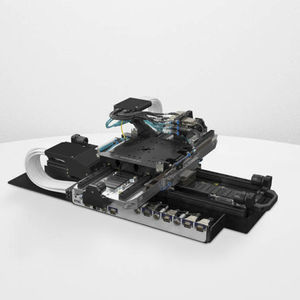

Stacked architecture positioning system VULCANO22/3-axisgantryfor wafer inspection and metrology

Add to favorites

Compare this product

Characteristics

- Number of axes

- 2/3-axis

- Features

- gantry

- Applications

- for wafer inspection and metrology, for the semiconductor industry, for clean rooms

- Other characteristics

- compact, stacked architecture

- Repeatability

1.5 µm

- Load

80 kg

(176.37 lb)- Stroke

365 mm

(14.37 in)- Speed

0.1 m/s, 1 m/s, 1.2 m/s

(0.33 ft/s, 3.28 ft/s, 3.94 ft/s)

Description

VULCANO2 is our gantry stacked-axes architecture combining our renowned ironcore motors, mechanical bearing and high-end optical encoders to deliver great geometrical performance at high dynamics.

When compared to our stacked CHARON2 family, the VULCANO2 mainly comes with higher duty cycle and payload capabilities. Its compact footprint maximises cost efficiency without compromising throughput and duty cycles.

Whether standard or customised, VULCANO2 ensures consistent repeatability and accuracy, even during extended operation. This platform is ideal for applications that require precision, such as overlay metrology and flip-chip processes on large plates.

Characteristics

Up to 6 degrees of freedom

Built-in vacuum supply and customer signal cables at chuck level

Here are the key features

Nanometer position stability

Ensures precise positioning accuracy over extended periods.

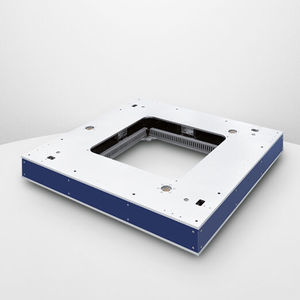

ISO 2 clean room compatibility

Suitable for controlled environments with stringent cleanliness requirements.

Tip-Tilt correction with the Z3TM+ combined module

Enables precise adjustment for optimal positioning.

Coarse Z function with the Z3TM+ combined module

Additional 12 mm electric lifting mechanism to enable wafer loading and offloading.

Built-in vacuum supply at chuck level

Facilitates efficient operation by ensuring proper material handling.

Short move and settle times

Quick response and stabilization for enhanced productivity.

VIDEO

Catalogs

DXRH rotary axis flyer

2 Pages

Related Searches

- Actuator

- Linear actuator

- Stage

- Electric actuator

- Linear stage

- Motorized stage

- Compact actuator

- DC actuator

- Linear unit

- 2-axis stage

- Precision actuator

- Anodized aluminum actuator

- Electric linear unit

- High-accuracy stage

- Mini actuator

- Precision linear unit

- High-performance actuator

- Linear positioning system

- Screw linear unit

- 3-axis positioning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.