- Products

- Catalogs

- News & Trends

- Exhibitions

8-axis positioning system TELICAportalfor the semiconductor industryhigh-accuracy

Add to favorites

Compare this product

Characteristics

- Number of axes

- 8-axis

- Features

- portal

- Applications

- for the semiconductor industry

- Other characteristics

- high-accuracy

Description

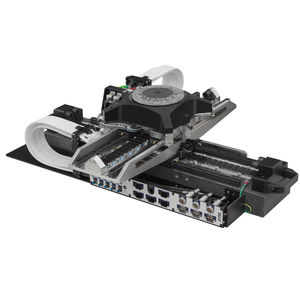

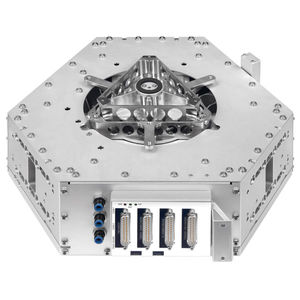

TELICA is a multi-axes platform primarily dedicated to semiconductor back-end applications. Its dual gantry architecture provides motion along 3 degrees of freedom, X, Y and Z, for a total number of 8 controlled axes. It is designed to fulfill the most challenging requirements of advanced die bonding processes (Flip-chip, Fan-out, 3D stacked packages), µ-LED bonding, dispensing applications and more.

By design, conventional motion system architectures are EITHER optimized for high positioning accuracy OR high throughput. Thanks to a very innovative motion system architecture, TELICA meets BOTH SIMULTANEOUSLY with ±1 µm global placement accuracy (blind move) at a throughput of 10 kUPH for a typical flip chip die bonding application and up to 180 kUPH for µ-LED bonding.

TELICA is available in 2 standard variants: variant 1 for Wafer Level Packages (WLP) with X410 x Y445 x Z30 mm travels and variant 2 for Panel Level Packages (PLP) with X750 x Y800 x Z30 mm travels.

TELICA introduces a new metrology approach drastically reducing the Abbé errors as well as the relative positioning mismatch between process tool and substrate. Multi-dimensional encoders ensure high placement accuracy while water cooled ironcore motors allow extreme duty cycles.

Main specifications

- ±350 nm local placement accuracy (moves with local alignment)

- ±1 µm global placement accuracy (blind moves)

- <10 minutes thermal transient (from cold start to hot working state)

- Up to 10 kUPH throughput for a typical flip chip die bonding application

- Up to 180 kUPH throughput for µ-LED bonding

- Up to 4 g acceleration in X, 6 g in Y and 7.5 g in Z

- Up to 2 m/s speed in X and Y and 1 m/s in Z

Catalogs

Related Searches

- Actuator

- Linear actuator

- Stage

- Electric actuator

- Linear stage

- Motorized stage

- DC actuator

- Linear unit

- 2-axis stage

- Precision actuator

- Electric linear unit

- Anodized aluminum actuator

- Mini actuator

- Precision linear unit

- Linear positioning system

- Screw linear unit

- Aluminum linear unit

- 3-axis positioning system

- Ball screw linear unit

- Compact positioning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.