- Products

- Catalogs

- News & Trends

- Exhibitions

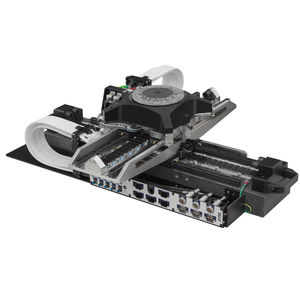

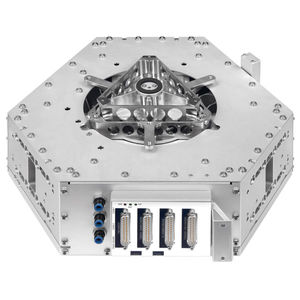

Precision linear axis TBSwith servo-motorball screwhigh-performance

Add to favorites

Compare this product

Characteristics

- Operation

- with servo-motor

- Type

- ball screw

- Other characteristics

- precision, aluminum, high-performance

- Stroke

50 mm

(1.969 in)- Speed

0.03 m/s

(0.1 ft/s)- Force

Max.: 13,500 N

Min.: 240 N

Description

The TBS is a high precision linear axis with a 1 Degree Of Freedom. This is a mechanical bearing based indirect drive linear axis providing outstanding performance in term of accuracy and precision in its category. The axis is controlled by a high performance low cogging servomotor and it uses a dual encoder feedback control scheme, which, while providing excellent performance, simplifies as well its commissioning. In complement to the advanced indirect drive control served at its heart by HEIDENHAIN Group encoder technologies, the axis features unmatched mechanical characteristics over the full stroke characterized for macro and micro motion.

This axis also includes specific design characteristics and options such as thermal decoupling of heat sources, high stiffness and micrometric hard stop that makes it particularly interesting for applications requiring process stability and safety.

With focus on easing semiconductor applications, the axis remains a match to all diverse markets and needs requiring solutions for high precision, high cleanliness, high stability and high accuracy.

Characteristics

• Total stroke: 50 mm

• Maximum payload: 45 kg

• Indirect drive - high precision ballscrew

• Dual encoder feedback

• Cleanroom compatibility: ISO2 (ISO1 optional)

• Option available such as micrometric hard stop.

Main specifications

• Bidirectional repeatability: ± 0.3 µm

• Micro-motion straightness of ± 50 nm

• Position stability: ± 10 nm

• Speed up to 0.03 m/s

• Acceleration up to 0.5 g

Catalogs

No catalogs are available for this product.

See all of ETEL S.A.‘s catalogsRelated Searches

- Actuator

- Linear actuator

- Stage

- Electric actuator

- Linear stage

- Motorized stage

- DC actuator

- Linear unit

- 2-axis stage

- Precision actuator

- Anodized aluminum actuator

- Electric linear unit

- Mini actuator

- Precision linear unit

- Linear positioning system

- Screw linear unit

- Aluminum linear unit

- 3-axis positioning system

- Ball screw linear unit

- Compact positioning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.