- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

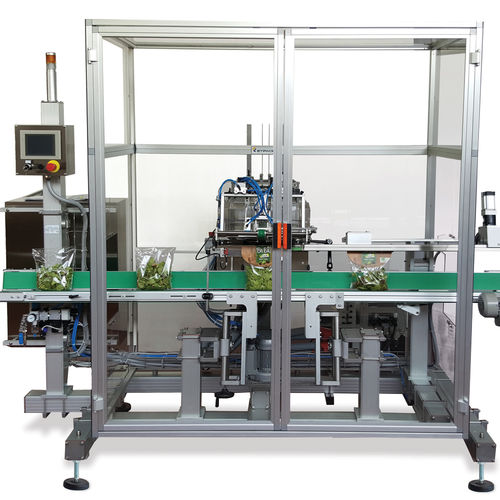

Automatic packaging machine horizontalbagfor paper

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Type

- horizontal

- Applications

- bag, for paper

- Domain

- for the food industry, for the cosmetics industry, for the chemical industry

- Throughput

40 p/h

Description

Fold and Fix is a carton header machine, an automatic system for the application of carton headers on bags containing e.g. pasta, candies, bakeries, etc

The carton header is made up of two main units:

a pair of conveyor belts that transport and hold the loaded packs in place

a placer unit model Clippy that would automatically pick and place headers on the bags; according to working conditions and carton headers, the system can work as well with a friction feeder model Whizzy

a hot melt unit for gluing the carton header to the sachet

an applicator unit that places and folds the cardboard on the package

a Product Stabilizer Device unit with opposing bands that completes the application by transporting the pack to the outlet, allowing the glue to adhere perfectly and solidify

The carton header has multiple functions: it serves as a tamper-evident seal since its removal involves tearing the bag or the cardboard itself, it allows the complete automation of the packaging process and it allows easy differentiation of the materials and their correct disposal, which is more and more a requirement for environmental sustainability.

The carton header with the Clippy Big placer is equipped with suction cups, picking carton header from a loading stacker and placing them on the packaging line.

The Clippy Big placer has a high-autonomy horizontal loading magazine.

Similarly, a friction feeder could carry the cards to the application point, while a placing device with suction cups proceeds with the laying of the cardboard on the bag.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Etipack‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Automatic labelling machine

- Packing machine for the food industry

- Bottle labeling machine

- Side labelling machine

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Labeller for the pharmaceutical industry

- Top labelling machine

- Bag packing machine

- Handheld dispenser

- Horizontal packing machine

- Wrap-around labelling machine

- Compact labelling machine

- Packaging machine for the cosmetics industry

- Packaging machine for the chemical industry

- High-speed label applicator

- Semi-automatic labelling machine

- Labeler for the chemical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.