- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

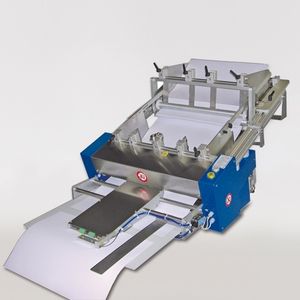

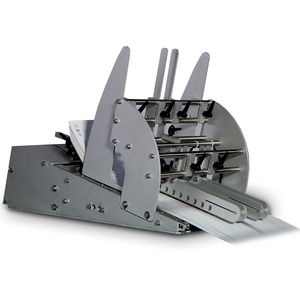

Flexible packaging feeding unit WHIZZY ROLLfor cartonsfor flat productsfor labels

Add to favorites

Compare this product

Characteristics

- Product applications

- flexible packaging, for cartons, for flat products, for labels, for paper, for the food industry, for rolls, for chemical products

- Other characteristics

- automatic

Description

The roll friction feeder Whizzy Roll is an automatic friction feeder specifically designed to feed coupons, backer cards, etc., from a roll format and to cut them to proper size.

The roll feeder provides for full automatic unrolling, cutting and feeding into the pakaging line with a speed up to 150 pcs/min. of different materials with a thickness up to 2 mm, such as paper, cartons, flexible packaging, plastic packaging materials, cleaning pads, food absorbent pads.

The machine is equipped with an orbiter cutter ensuring a clean and precise cut to proper size.

Cutting size is operated from a keyboard by setting length paraments, in order to vary pitch length according to actual manufacturing needs.

Features of the feeder

• Feeding from roll format

• Mechanic unwinder

• Brushless drawing with step movement by stop control

• Orbiter cutter with saw-toothed and brushless motor actioning

• Stop sensor on product distribution

• Separate control box (remote terminal up to 3 m) with integrated PLC

• Separate control panel (remote up to 3 m)

• Brushless motor

• Programming keyboard

Ancillary devices

• Base support structure

• Customized support structure

Features:

Dispensing speed:

≤ 60 m/min

(150 pcs/min depending on the products step)

Dim. prod. lunghezza: 55 - 300 mm

Product sizes L: 50 - 150 mm

Product sizes W: 1÷2 mm

Product dispensing: Horizontally

Dispensing unit width

366 mm

Motor type: Brushless

Size L - W - H: 877x672x500mm

C.B. dimensions L - W - H: 600x200x600mm

Power supply: 230 V, 50-60 Hz

Electrical input: 920 W

Electric protection: IP 54

VIDEO

Catalogs

Whizzy Roll

1 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.