Duct burner VEINAIRFLAMnatural gasdirect firedfor heating

Add to favorites

Compare this product

Characteristics

- Type

- duct

- Power source

- natural gas

- Firing

- direct fired

- Applications

- for heating

- Other characteristics

- low-NOx

- Power

300 kW

- Output pressure

Min.: 1.2 mbar

(0.02 psi)Max.: 3 mbar

(0.04 psi)

Description

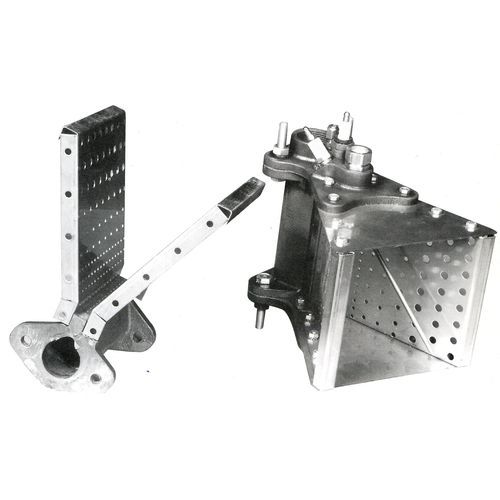

The VEINAIRFLAM burners are raw gas burners designed for direct-fired fresh air or partially mixed

air heating. They are the basic standard for low, middle or semi high temperature (up to 850 °C)

make-up applications in many industrial fields.

The VEINAIRFLAM burners produce a uniform, odorless, and smokeless flame ideal for heating fresh

air in make-up and process air heating applications. VEINAIRFLAM burners design provides stable

operation over a wide range of velocities, inputs, and fuels.

The VEINAIRFLAM burners design make possible to operate the burner without a combustion air

blower. The burner with no moving parts depends on the air speed across the burner from the airflow

in the duct. The turbulence effect created by the mixing plates is heightened by provision of a

diaphragm air plates accelerating the air speed all around the burner’s location. This results in a slight

pressure drop in the air to be heated. The pressure drop or pressure loss practically does not exist

with the VEINAIRFLAM-V series who is designed with a air combustion blower integrated wich

doesn’t require diaphragm or profiles plates.

The VEINAIRFLAM burners are directly mounted in the airstream to be heated and a specific air

velocity is created all around the burner to provide progressive aeration of the space between the

burner air/gas mixing plates. The oxygen necessary for combustion is taken directly from the air witch

enters through the mixing plates hole’s and mixes gradually with the gas. The burner is therefore a

burner with a very large excess air for complete gas combustion. 100 % efficiency (on gas Pci).

VIDEO

Catalogs

VEINAIRFLAM

12 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.