- Industrial machines and equipment

- Welding and Assembly

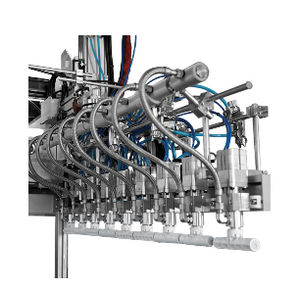

- Glue dispenser

- Europoliuretani Srl

Glue dispenser 1K IBCmanualhigh-volumeIBC

Add to favorites

Compare this product

Characteristics

- Dispensed product

- for glue

- Operating mode

- manual

- Other characteristics

- high-volume, IBC

Description

The 1K IBC dispenser for monocomponent glues, with a capacity of 1000 litres of the chemical product, is suitable for operators in sectors where a large quantity of the product is required. Generally this type of system is combined with automated systems for application of the glue.

TECHNICAL ASPECTS

• Chemical packaging capacity: 1000 litres.

• Chemical suitable for the system: with and without additives.

• Piping: heated.

• Cube housing base: with containment basin.

• Pump: geared with electric motor.

• Flow rate on request.

• Temperature control/setting: by means of a temperature controller.

• Flow regulation: through potentiometer for motor speed adjustment.

• Standard gun version installed.

• Airbrush: spray by liquid nebulisation.

The cube, in which the polyurethane glue is present, is located on top of a carbon steel frame, whose structure allows it to also act as a containment basin, designed specifically in case of accidental spills of the chemical product. The pumping system, the storage tank and the electrical control panel are housed in the same frame.

The gear pump, which takes the chemical from the cube to start it at the dispensing gun, is driven by an electric motor and in addition it is possible to install a magnetic coupling (optional) between the pump and the motor in order to avoid any physiological leaking of the product from the gaskets. In the long term, with this option, possible blocking of the pump caused by the reaction of the chemical with the air is avoided.

The 10-litre (heated) tank has been designed to avoid any problem when the product is about to finish.

Catalogs

Dispenser

13 Pages

Other Europoliuretani Srl products

Polyurethane adhesives systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.