Polyurethane glue dispenser 2K SERIE 30-100manualtwo-componentfor panels

Add to favorites

Compare this product

Characteristics

- Dispensed product

- polyurethane glue

- Operating mode

- manual

- Other characteristics

- two-component, for panels

Description

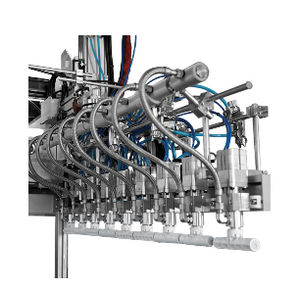

DISPENSER FOR BI-COMPONENT POLYURETHANE GLUES

The 2K dispenser can be configured with 30- or 100- litre tanks and can mix components either with or without additives. If the additives contained within the components are abrasive, Europoliuretani is able to provide a special treatment to the pump to prolong its life.

Technical aspects

• Chemical packaging capacity: 30 or 100 litres.

• Chemical suitable for the system: with and without additives.

• Piping: heated.

• Pump: geared with electric motor.

• Flow rate on request.

• Temperature control/setting: by means of a temperature controller or PLC.

• Flow regulation: through potentiometer for motor speed adjustment or PLC.

• Standard gun version installed: with static mixing system.

The 2K dispensers are built in a solid carbon steel frame, on which components of internationally recognised high quality brands are installed: SIEMENS, BUCHER, WIKA, KELLER, PEPPERL + FUCHS etc.

The gear pumping system takes the chemical from the tanks (the latter can be heated and pressurised up to 2 bar) and sends the fluid to the dispensing gun via a special heated pipe.

Thermostatation of the chemical lines and of the tank improves fluidisation of the product in cold temperature conditions and enables a greater reaction speed of the glue itself. Usually, the machine is supplied with a standard control panel to control the main functions of the machine, but at the customer’s request a PLC can be installed to ensure better control of the system through additional applications: it is an example of the possible connection to a robotised system.

Catalogs

No catalogs are available for this product.

See all of Europoliuretani Srl‘s catalogsOther Europoliuretani Srl products

Polyurethane adhesives systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.