- Environment - Health - Safety

- Air Treatment and Noise Management

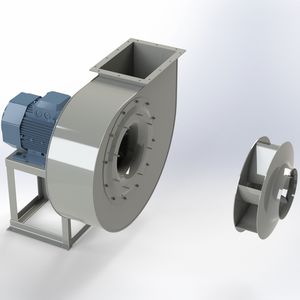

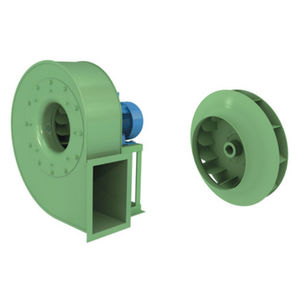

- Centrifugal fan

- EUROVENTILATORI INTERNATIONAL

Centrifugal fan EUc seriessuctionfor chemical applicationsmedium-pressure

Add to favorites

Compare this product

Characteristics

- Configuration

- centrifugal

- Function

- suction

- Applications

- for chemical applications

- Other characteristics

- medium-pressure, with airfoil blades

- Air flow

Max.: 145,000 m³/h

(5,120,626.675 ft³/h)Min.: 1,300 m³/h

(45,909.067 ft³/h)

Description

Use: the hight output centrifugal fans of this series are suitable for the suction of dusts, fumes , granulates, sawings or also wooden shavings of minimum sizes and materials in general mixed with air excluding filament material.

Their main feature is that of joining up the high output (deriving from the use of a fan wheel with reversed blades, special profile) with the suitability of transporting materials mixed with air. Besides, these fans are distinguished by a very flat curve of the absorbed power, such as to not overload the motor neither when working with free throats.

They are assembled in carpenter shops, mechanical industries, cement factories, ceramic factories, tanneries , foundries,in themolinary and chemical industries, and in all those applications where it is necessary to transport harmuful air with max. temperature of 90° C.

For temperatures of the transported fluid higher than 90°C up to 350°C a small heat stopping fan is splined to the shaft between support and scroll; besides the fan is painted with a special aluminium paint suitable for high temperatures.

ErP: these fans are covered by Directive 2009/125/EC. This law does not apply in the following cases:

- Operation in potentially explosive atmospheres (ATEX)

- Operation with high temperatures (fans designed with cooling fan)

- Operation with temperatures below -40°C

- Working in toxic, corrosive or abrasive enviroments (use of material such as AISI 304, AISI 316, manganese steels).

These series are centrifugal backward curved fans and therefore expected Ntarget = 61 (Reg. UE N.327/2011).

ErP calculations take into account efficiency IE2 motors conforming to IEC 60034-30.

Catalogs

No catalogs are available for this product.

See all of EUROVENTILATORI INTERNATIONAL‘s catalogsOther EUROVENTILATORI INTERNATIONAL products

Medium Pressure

Related Searches

- Radial fan

- Propeller fan

- Ventilation fan

- Extractor fan

- Fan for industrial applications

- Electrically-powered fan

- Cooling fan

- Aluminum fan

- Exhaust fan

- Backward curved fan

- EC motor fan

- High-pressure fan

- Low-noise fan

- Direct-drive fan

- Suction fan

- Roof-mounted fan

- Drying fan

- Medium-pressure fan

- Low-pressure fan

- Pneumatic conveying fan

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.