- Production Machines

- Other Manufacturing Equipment

- Wood production line

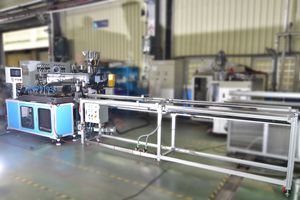

- Everplast Machinery Co., Ltd.

Panel production line for woodwith mixer

Add to favorites

Compare this product

Characteristics

- Finished product

- panel, for wood

- Other characteristics

- with mixer

Description

01- Circular Economy Crushing + Grinder System

02- Circular Economy Mixer System

In the production process of Wood Plastic Composite (WPC), natural fiber can mix with 30%-80% of the polymer. Therefore, the selection of natural fiber (sawmill, chipboard, rice husk, etc.) is important. All natural fiber must pulverize as 40mesh~120mesh of particle size.

03- Circular Economy Production Line

The use of natural fibers in extruded profiles is becoming increasingly popular. Attempts have been made to develop new features of finished wood-plastic composites (WPC), such as PP/PE resin mixing 40-80% natural fiber or PVC mixing 40-70% natural fiber. To meet the quality requirements, Everplast has developed a segmented twin screw extruder with special single screw extruder line as well as a parallel twin screw extruder with special single screw extrusion line combining tooling die head and all downstream equipment.

04- Application

Building Materials from PE/PP/PVC Recycle

With more than 20 years experience in this filed, we, Everplast see ourself as a reliable partner. As the leader of extrusion industry, we have successfully installed more than 24 PE synthetic wood extruder in Saudi Arabia since 2005, including 65mm, 75mm, 85mm and 100mm single screw extruder. The synthetic wood material is be made from wasted film, bottle..etc.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Everplast Machinery Co., Ltd.‘s catalogsOther Everplast Machinery Co., Ltd. products

WHOLE PLANT

Related Searches

- Production machine

- Automatic making machine

- Pipe making machine

- Profile making machine

- Panel making machine

- Braiding machine

- PLC-controlled making machine

- Wood product production line

- Ultrasonic production machine

- Folding production line

- Mask production line

- Cardboard production line

- Production line with mixer

- Wood production line

- WPC foam production line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.